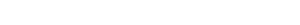

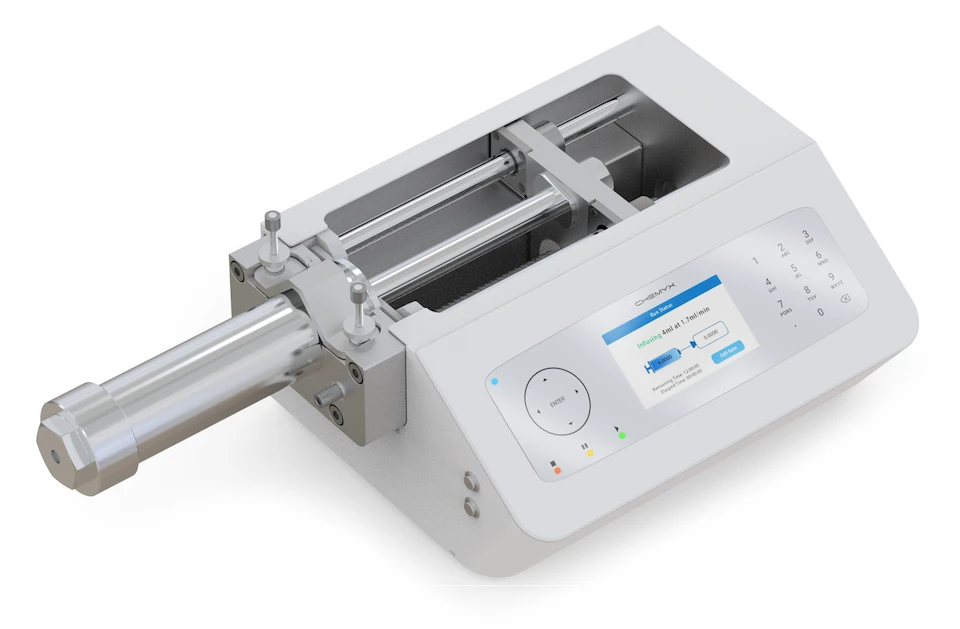

Fusion HP

1 TON PUSHING FORCE

HIGH PRESSURE SYRINGE PUMP

Fusion HP high-pressure syringe is a heavy-duty high-pressure syringe pump designed for elevated pressures in research, industrial, and manufacturing applications. This system delivers 1 Ton (2200 lbs) of pushing force and is the most powerful benchtop linear pump system on the market. This specialized high-pressure syringe pump is designed for demanding conditions associated with supercritical fluids, hydraulic fracturing, and nano-encapsulation which exist at temperatures and pressures beyond their critical points.

The Fusion HP high-pressure syringe pump is engineered with materials and components that can withstand challenging conditions often at pressures exceeding 10,000 psi, including heavy-duty drive shafts, high-performance drive transmission, and corrosion-resistant metal outer enclosure.

Like all Chemyx syringe pumps, the Fusion HP employs an advanced micro-stepping stepper motor to precisely regulate and maintain a stable and controlled flow rate. Additionally, these pumps have optional pressure detection and syringe heaters allowing researchers and engineers to fine-tune experimental conditions for materials science, pharmaceuticals, and environmental process analysis.