Precise fluid delivery is essential for credible scientific research. In the laboratory, accuracy forms a critical foundation for reproducible data and valid experimental outcomes. When experimental integrity depends on exact fluid dosing—whether for microfluidics, pharmaceutical formulation, advanced analytical chemistry, or material discovery—selecting the appropriate syringe pump is foundational for reliable results.

This article will cover the following sections:

- Understanding Laboratory Syringe Pump Requirements

- Precision Syringe Pumps for Laboratory Applications

- Essential Features for Laboratory Syringe Pumps

- Selection Criteria for Laboratory Applications

- Applications in Research Laboratories

- Maintenance and Operational Considerations

- Selecting Your Syringe Pump

- Essential Syringe Pump Checklist

- Risks & Caveats

- Frequently Asked Questions

Since its inception, Chemyx has focused on providing laboratory fluidic solutions, offering instruments designed to support scientific research and discovery. The brand’s advanced syringe pump solutions are known for their precision, reliability, and reproducible results, making them valuable for complex research across numerous applications.

Chemyx syringe pumps are designed to support your research, with the following features:

- High Accuracy: Achieve flow rate precision of ±0.35% or better [1]. This level of accuracy is important for sensitive applications where even slight deviations can impact results.

- Enhanced Data Integrity: Support consistent and reproducible results, bolstering the credibility of your findings and making your work and data more robust.

- Accelerated Research: Streamline complex protocols with advanced programming features, minimizing manual intervention, obtaining results at a faster rate, and significantly contributing to efficiency in your lab.

Modern laboratory syringe pumps are sophisticated analytical instruments, extending beyond simple fluid dispensers. They integrate advanced functions such as programmable flow rates, multi-channel operation, infuse or withdraw modes, and precision fluid management across volumes from microliters to hundreds of milliliters, supporting consistent and reproducible experimental results.

Understanding Laboratory Syringe Pump Requirements

While easily confused with medical infusion pumps, laboratory syringe pumps prioritize distinct design parameters for research applications. These often necessitate significantly higher precision, broader flow rate ranges, higher pressure, and enhanced chemical compatibility. As noted by Air-Tite Products, laboratory pumps prioritize experimental reproducibility, while medical pumps focus on patient safety [2]. These specialized requirements directly influence experimental reproducibility and the integrity of your data.

When selecting a pump, several key performance parameters warrant close consideration:

- Flow rate accuracy: For precision-critical work, high-quality pumps should offer high accuracy. For instance, Chemyx models such as the Fusion 100X and Fusion 6000X offer an accuracy of ± < 0.35% [1] [3]. The Fusion 4000X and also achieves this precision .

- Syringe compatibility: Pumps should accommodate a wide array of syringe sizes and materials. A versatile pump like the Chemyx Fusion 6000X can handle syringe capacities ranging from 0.5µL to 300mL [3], adapting to diverse experimental needs and specifications.

- Pressure capabilities: While many standard lab applications operate below 100 psi, specialized high-pressure units are available. For instance, the Fusion 6000X can deliver pressures up to 2000 psi when equipped with a pressure sensor [4], suitable for demanding applications such as those involving highly viscous fluids or small-bore tubing.

- Control interfaces: Modern pumps often offer USB, RS232, TTL, and LCD touchscreen operation for integration into existing lab setups. Many Chemyx models are compatible with Python, LabVIEW, and MATLAB [5].

- Multi-step programming: This feature is valuable for executing complex protocols and automating workflows without constant manual intervention. Many Chemyx models, like the Fusion 200X, offer robust multi-step programming [5].

Precision Syringe Pumps for Laboratory Applications

For researchers seeking the best precision syringe pumps and reliability, Chemyx offers a range of solutions. The Fusion series of syringe pumps, for example, is designed considering the specific requirements of demanding research applications.

Chemyx Fusion Series Overview

| Model | Key Features | Flow Rate Range | Syringe Capacity | Linear Pushing Force | Accuracy |

|---|---|---|---|---|---|

| Fusion 100X | Dual-channel, compact, precise dosing | 0.0001 µL/min to 157 mL/min [1] | 0.5µL to 60 mL [1] | 45 lb [1] | ± < 0.35% [1] |

| Fusion 200X | Dual-channel, programmable multi-step mode | 0.0001 µL/min to 84.7 mL/min [5] | 0.5µL to 60 mL [5] | 45 lb [5] | ± < 0.35% [5] |

| Fusion 4000X | Dual-independent channels, programmable | 0.0001 µL/min to 170.5 mL/min[6] | 0.5µL to 100 mL [6] | 85 lb [6] | ± < 0.35% [6] |

| Fusion 6000X | Enhanced high-pressure, higher linear force | 0.0001 mL/min to 408 mL/min [3] | 0.5µL to 300 mL [3] | 700 lb [3] | ± < 0.35% [3] |

- The Fusion 100X provides dual-channel operation with flow rates from 0.0001 µL/min to 157 mL/min [1], suitable for microfluidics, injections into reactors, and neuro-drug delivery.

- For multi-channel experiments requiring independent fluid handling, the Fusion 4000X offers dual-independent infuse and withdraw channels [6]. This capability is important for applications such as lipid nanoparticle formulation and microfluidic mixing protocols in biopharmaceutical research, where cross-contamination or timing mismatch could affect an experiment [6].

- In demanding high-pressure scenarios, like those found in materials research or industrial R&D, the Fusion 6000X is a notable option, capable of delivering up to 2000 psi while maintaining precise flow control when used with a pressure sensor [4].

Essential Features for Laboratory Syringe Pumps

Programmable Flow Profiles

Complex research protocols rarely involve a single, continuous flow rate. Instead, they often require varied fluid delivery across different phases. Multi-step programming allows researchers to create automated sequences that combine different flow rates, volumes, and timing profiles. This feature is valuable for applications like gradient generation, cell culture perfusion, and analytical method development. Many Chemyx models, like the Fusion 200X, offer robust multi-step programming [5], which can save time in manual adjustment and contribute to experimental consistency.

Chemical Compatibility

Lab environments expose equipment to a vast array of solvents and reagents. Syringe pumps should be constructed with materials that can withstand these chemicals to support long-term reliability and help prevent contamination. Syringe pumps built with chemically resistant materials, such as stainless steel fluid paths and PTFE seals, are important. For superior chemical resistance over traditional plastic, stainless steel syringes are often preferred, particularly in high-pressure or chemically aggressive applications.

Control Integration

The modern laboratory often incorporates automation, and seamless integration of instruments is key. Contemporary syringe pumps often provide multiple control interfaces, including LabVIEW and MATLAB compatibility. For instance, many Chemyx models, like the Fusion 200X, offer robust connectivity options and come with drivers that facilitate complex experimental setups and advanced data acquisition [5]. This helps ensure your pump can become a reliable part of your automated workflow.

Selection Criteria for Laboratory Applications

Choosing the right syringe pump requires careful consideration to help ensure it aligns well with your specific research needs. Here’s a practical guide to help you make an informed decision:

- Define your flow rate needs: Precisely identify your required flow rate range. Microfluidics typically demands ultra-low rates (nanoliters/minute to microliters/minute), while preparative work might necessitate milliliters/minute. Select a pump that not only covers your experimental needs but also offers appropriate resolution at these ranges.

- Syringe Volume Compatibility: Consider both the minimum and maximum syringe volumes your experiments will require. For parallel processing or extended operations, explore options like multi-syringe expanding racks that can accommodate multiple syringes simultaneously, enhancing throughput and reducing downtime.

- Pressure Requirements: Most standard lab applications will stay below 100 psi. However, if you’re working with viscous fluids, small-bore tubing, or high-flow resistance systems, you’ll need higher pressure capabilities. Accurately assess your maximum operating pressure to avoid equipment limitations.

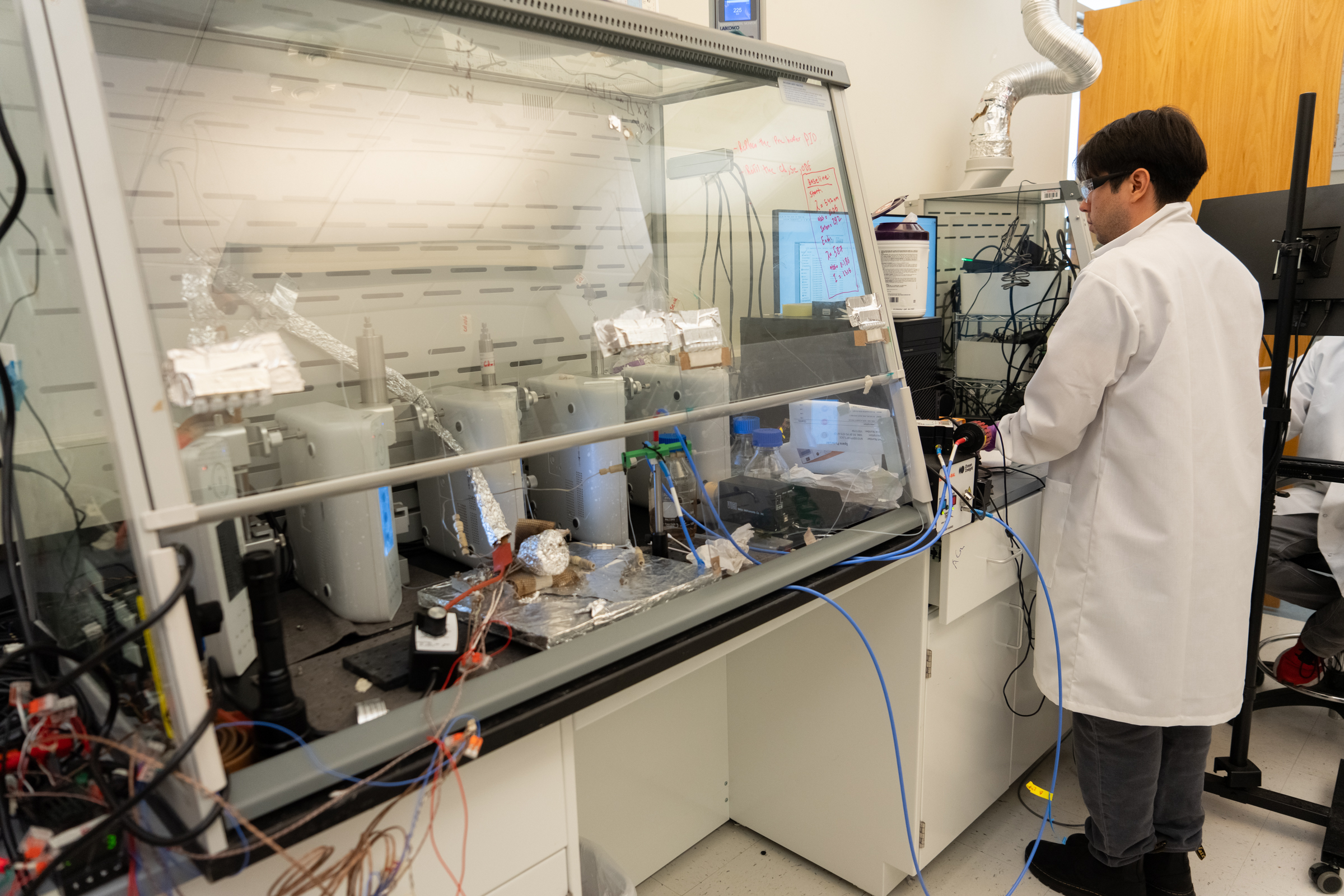

Applications in Research Laboratories

The versatility of modern syringe pumps makes them highly valuable across a spectrum of research disciplines.

Microfluidics and Lab-on-Chip Systems

In the realm of microfluidics, where sample volumes are minuscule, precise control of small volumes with flow stability is important. Syringe pumps provide the consistent pressure and flow rate control important for reliable chip-based assays, microscale reactions, and developing sophisticated lab-on-chip devices [7].

Analytical Chemistry

From mass spectrometry calibration to HPLC sample preparation and analytical method development, these applications often rely on reproducible flow rates and precise volume control. Modern syringe pumps, with their ability to program complex flow profiles, are instrumental in achieving consistent gradient elution and automated sample introduction.

Biomedical Research

In biomedical fields, such as cell culture perfusion, drug delivery studies, and tissue engineering, sterile and precise fluid handling is important. Syringe pumps enable controlled delivery of media, growth factors, and therapeutic compounds with reduced contamination risk, which is important for maintaining cell viability and experimental integrity.

Maintenance and Operational Considerations

To help ensure your syringe pump remains a reliable tool, integrating maintenance into your lab routine is essential.

Regular Calibration

Regular calibration, using gravimetric or volumetric methods, is key to helping maintain pump accuracy over time. Documenting these results supports compliance with quality standards and provides a performance history.

Preventive Maintenance

Routine preventive maintenance can extend the lifespan of your pump and help preserve its optimal performance. This includes periodic cleaning, inspection and replacement of seals and gaskets, and verification of motor performance.

Documentation and Validation

For laboratories operating in regulated environments, comprehensive documentation is not only good practice but often a requirement. This includes installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) protocols. Maintaining detailed records of all maintenance and calibration activities is valuable for audits and supporting data integrity.

Quick Steps: Selecting Your Syringe Pump

Navigating the options can sometimes feel overwhelming, so here’s a concise guide to streamline your decision-making process:

- Define your flow rate needs: Determine the minimum and maximum flow rates required for your typical experiments.

- Assess syringe compatibility: Match the pump’s capacity to your desired syringe volumes and materials (glass, plastic, stainless steel).

- Evaluate pressure demands: Identify if your applications involve viscous fluids or narrow tubing that necessitate standard or high-pressure capabilities.

- Consider multi-channel options: Decide if independent fluid delivery for multiple channels is necessary for parallel experiments or complex mixing.

- Check for programming flexibility: Ensure the pump supports multi-step protocols if your research requires dynamic fluid profiles.

- Verify chemical resistance: Confirm that the pump’s fluid path materials are compatible with the specific reagents you’ll be using.

Essential Syringe Pump Checklist

Use this checklist to help ensure you cover important aspects before making a final decision:

- Flow Rate Range: Is it sufficient for all planned applications, from nano-scale to bulk delivery?

- Accuracy & Reproducibility: Does it meet your experimental requirements (e.g., ±0.35%)?

- Syringe Volume Range: Can it accommodate all your desired syringe sizes and types?

- Pressure Rating: Is it adequate for your fluid viscosity and tubing resistance, with a safety margin?

- Control Interface: Does it integrate with your existing lab setup (e.g., USB, LabVIEW, touchscreen)?

- Programmable Profiles: Does it offer multi-step programming for automated workflows and complex sequences?

- Chemical Compatibility: Are the fluid path materials resistant to your specific reagents and solvents?

Risks & Caveats

Even advanced syringe pumps come with considerations. Here are a few things to keep in mind:

- Syringe Material Limitations: While pumps are robust, the syringe material itself can limit pressure tolerance or chemical compatibility. Glass syringes, for example, are less chemically reactive but can be prone to breakage under high pressure.

- Fluid Viscosity: Highly viscous fluids can significantly impact flow rate accuracy and may require specialized high-pressure pumps and larger bore tubing to achieve desired results.

- Tubing and Connections: The entire fluidic path, including tubing, connectors, and valves, should be compatible with your operating pressures and chemicals. Leaks or pressure drops can significantly compromise experimental integrity.

- Calibration Drift: All precision instruments can experience calibration drift over time due to wear and tear or environmental factors. Regular calibration is not merely optional; it is essential for maintaining data reliability.

- User Error: Even with automated programming, incorrect setup, improper syringe loading, or overlooked maintenance steps can lead to inaccurate results. Training and adherence to protocols are important.

Frequently Asked Questions (FAQ)

Q: Can a single syringe pump handle both infuse and withdraw functions?

A: Yes, many modern laboratory syringe pumps, including several models in the Chemyx Fusion series, are designed to handle both infuse (push fluid) and withdraw (pull fluid) operations [8]. This capability is particularly useful for applications requiring controlled recirculation or sample collection.

Q: What’s the difference between a research syringe pump and a medical infusion pump?

A: Research syringe pumps are engineered for precision, broad flow rate ranges (from picoliters to milliliters per minute), and chemical compatibility for diverse lab reagents, prioritizing experimental reproducibility [2]. Medical infusion pumps, on the other hand, are designed primarily for patient safety, typically featuring narrower, pre-set flow rates and focusing on delivering pharmacological agents, often with built-in alarm systems for occlusions or air bubbles [2].

Q: Are Chemyx syringe pumps compatible with automation software like LabVIEW or MATLAB?

A: Yes, many Chemyx syringe pumps, including the Fusion 200X and other models in the Fusion series, offer control interfaces like USB and RS232. They also come with drivers that enable seamless integration with automation software such as Python, LabVIEW and MATLAB, allowing for advanced experimental control and data acquisition [5].

Conclusion

As we look into the future of laboratory research, precision syringe pumps continue to be essential tools. Their combination of precise flow control, programmable operation, and robust construction enables researchers to achieve consistent, reproducible results across an expanding array of applications. When it’s time to choose your lab’s next syringe pump, prioritize models that offer the specific features, performance characteristics, and reliability your research demands. For precision syringe pumps engineered for scientific inquiry, Chemyx provides viable options.

To optimize your laboratory’s fluid handling capabilities and support the integrity of your experimental data, consider exploring the range of precision syringe pumps and accessories available from Chemyx to identify a suitable solution for your specific research needs today. If you have further questions, our team is ready to assist you in selecting the appropriate pump for your application. Contact us at info@chemyx.com to learn more.