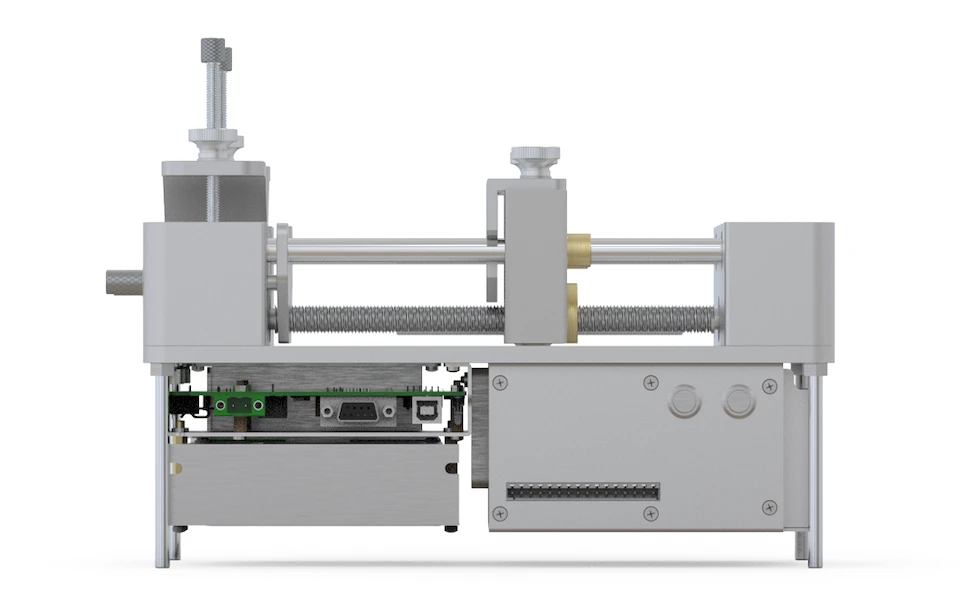

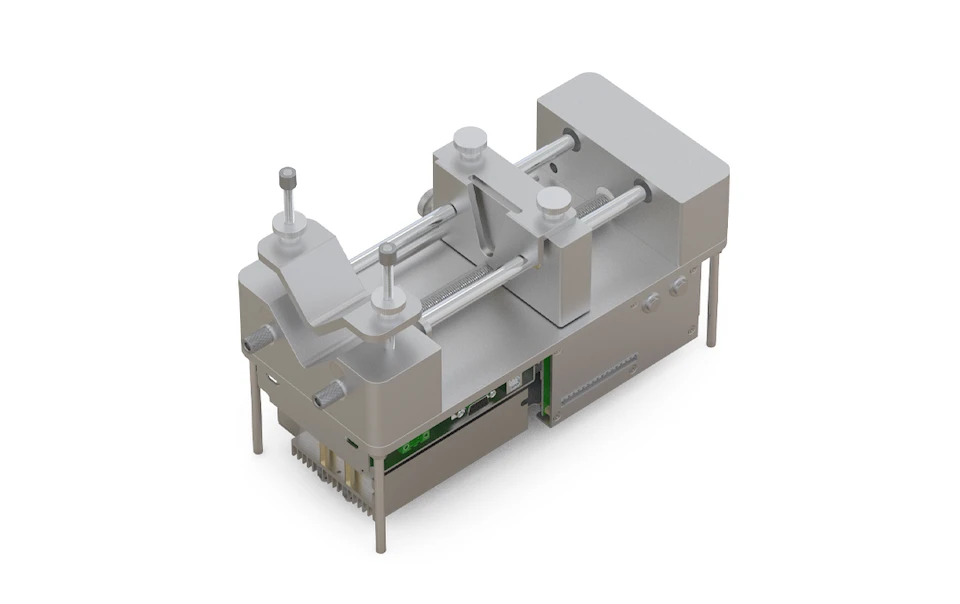

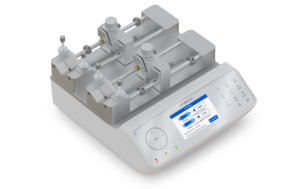

OEM Fusion 6000X Syringe Pump

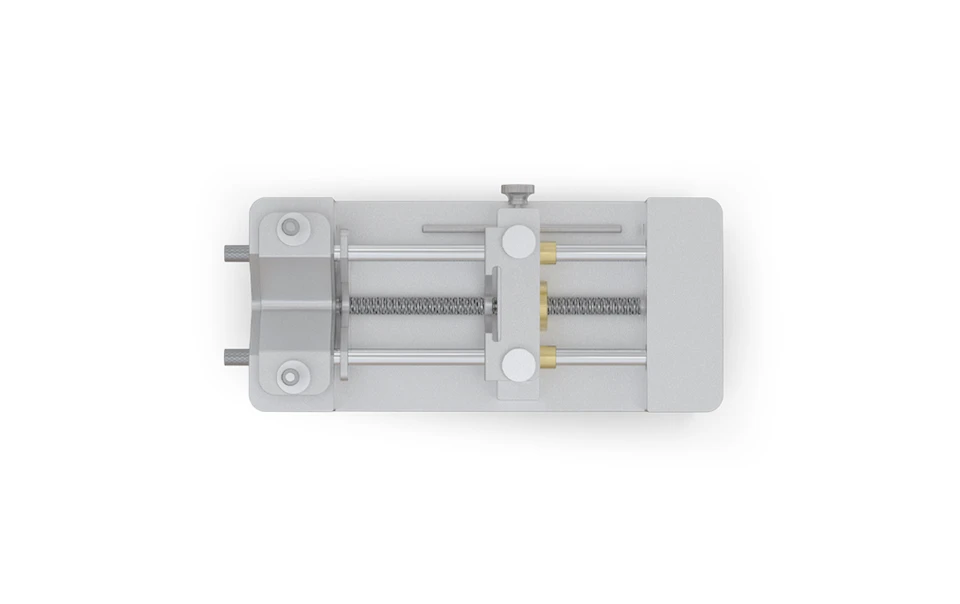

Chemyx Fusion 6000X OEM module is a bolt-on high-pressure syringe pump module designed for integration into customer-made analytical instruments for dosing viscous solutions and semi-solid material against pressure with microfluidic pump precision.

With the same specifications as the portable Fusion 6000X, the bolt-on Fusion 6000X OEM high-pressure syringe pump is configured with the following unique features:

- 700 lbs linear pushing force

- Priming buttons to easily adjust the plunger's position

- Modular 4 syringe expansion pack

- Can add on a syringe heater jacket to warm the contents of one syringe.

- Capable of adding a pressure sensor for syringe pressure monitoring and control

These features allow the Fusion 6000X OEM module to work against high back pressure while warming a syringe's contents with pressure monitoring and control. Like other OEM modules, the Fusion 6000X OEM high-pressure syringe pump can be controlled by a computer via TeraTerm or a customer-created computer program.

- Syringe pump for high-pressure applications

- Temperature and pressure control options

- Prime Buttons for easy syringe adjustment

- Holds stainless-steel syringes from 5mL to 300mL

- Rates from 0.0001 mL/min to 408 mL/min

- Control via touchscreen, USB, RS232, TTL

- Free Programmable Mode Included

- 2-Year Limited* Warranty

- Patent Pending

- Power Adapter Included

- Available Accessories