Industrial programmable syringe pumps are fundamental instruments in modern manufacturing, research, and high-tech industrial processes. These devices deliver exceptional and consistent fluid dosing, which is a non-negotiable requirement for applications where accuracy and reliability directly impact outcomes. From pharmaceutical development to microelectronics fabrication to core flooding, the ability to control fluidics with high reproducible rates is critical. As a leading manufacturer of high-performance fluidic instruments, Chemyx Inc. provides the programmable precision and high pressure syringe pumps that laboratories and industries rely on for their most difficult applications.

Topics Covered:

- What Makes a Syringe Pump “Industrial” and “Programmable”?

- Key Features of a High-Performance Industrial Programmable Syringe Pump

- Critical Applications for Modern Industry

- How to Select the Right Large Volume Syringe Pump

- Precision, Durability and Support

What Makes a Syringe Pump “Industrial” and “Programmable”?

An industrial programmable syringe pump is a specialized, motor-driven device engineered to dispense or withdraw fluid from a syringe at a meticulously controlled rate. Unlike medical-grade infusion pumps designed for patient use, industrial and research pumps, such as those manufactured by Chemyx, are built for laboratory, production, and industrial environments. It is critical to note that these pumps are not intended for use on humans, as their design priorities and regulatory approvals are fundamentally different.

The “programmable” functionality is what sets these pumps apart for complex applications. Users can program multi-step dispensing routines, create variable flow rates, and automate entire fluid handling procedures. This is typically accomplished through an intuitive onboard interface or via computer control using standard communication protocols like USB, RS232, or TTL.

The core working principle involves a stepper motor that drives a lead screw. This screw moves a pusher block, which precisely advances or retracts the plunger of a mounted syringe, resulting in a smooth, continuous flow of fluid [1].

Key Features of a High-Performance Industrial Programmable Syringe Pump

Unmatched Precision and Accuracy

In industrial settings, consistent results depend on reproducible processes. A key performance indicator for a syringe pump is its ability to deliver pulseless, steady flow rates. This ensures that the exact amount of fluid is dispensed every time, eliminating variability in product quality or experimental data. The Chemyx Fusion series of syringe pumps is at the forefront of high-precision fluid delivery, offering exceptional accuracy for sensitive applications. For process validation, accuracy for Chemyx Fusion series syringe pumps are best verified by using a high-quality glass syringe filled with distilled water and then measuring the dispensed volume or mass over a set period.

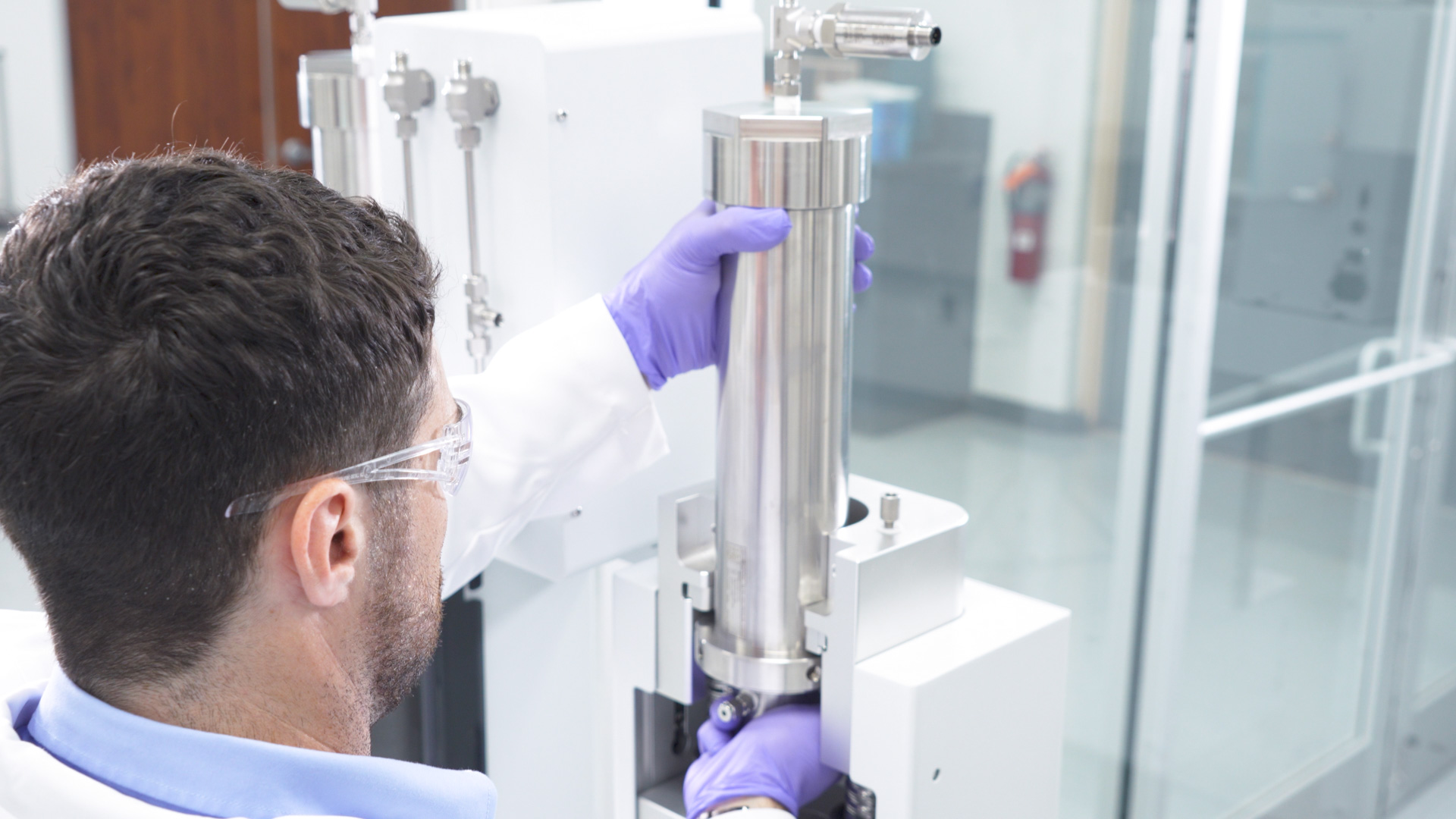

Robust Construction for Demanding Environments

Industrial environments can be harsh, requiring equipment built for longevity and resilience. A high-performance industrial pump features a heavy-duty construction, often with a machined metal frame and chemical-resistant hardware. For example, Chemyx syringe pumps are fabricated with durable materials and stainless steel to withstand accidental spills and resist corrosion from aggressive chemicals. For particularly challenging high-pressure applications, models like the Chemyx HP series deliver substantial linear pushing force, up to 10 tons. For continuous flow processes in demanding or hazardous environments, specialized systems like the Chemyx HP6 and HP6-CF are available. This robust design ensures long-term operational stability and reliability.

High Force for Large Volume and Viscous Fluids

Dispensing viscous materials or working against significant back pressure requires substantial linear force. A large syringe pump or large volume syringe pump designed for these tasks must have a powerful motor and drive mechanism. When using a large-diameter syringe, the force required to move the plunger increases significantly. Chemyx offers a wide range of all syringe pumps, including models like the Fusion 6000X, which provides 700 lbs of linear force and can accommodate syringes up to 300 mL.

Critical Applications in Modern Industry

Manufacturing and Continuous Flow Dispensing

Programmable syringe pumps are integral to achieving the precise fluid control required in advanced manufacturing. They are utilized in a variety of processes, including:

-

Additive Manufacturing (3D Printing): Extruding specialized polymers or binding agents.

-

Electronics Assembly: Dispensing precise amounts of adhesives, solder paste, or conformal coatings.

-

Pilot Plants: Scaling up chemical reactions with accurate reagent dosing.

-

Specialty Chemical Production: Infusing reactants at a controlled rate for continuous flow synthesis, an application where a continuous flow pump model excels.

Pharmaceutical and Chemical Development

In pharmaceutical and biotechnology laboratories, syringe pumps are essential tools for research and development. The Chemyx Fusion series is well-suited for applications like cell perfusions and microfluidic mixing for drug formulation. In the chemical industry, these pumps facilitate experiments such as core flooding analysis in petrochemical research, which often demands the capabilities of high-pressure pumps like the Chemyx HP series to simulate reservoir conditions. The reproducibility enabled by these pumps helps accelerate research cycles and generate reliable data.

OEM Integration into Analytical Instruments

OEM (Original Equipment Manufacturer) syringe pump modules are compact, “bolt-on” fluidic devices designed for seamless integration into larger, more complex systems. These modules can be found in analytical instruments like mass spectrometers, chromatographs, and custom-built manufacturing machinery. Chemyx OEM modules feature a plug-and-play design with USB and RS232 communication, enabling fast and straightforward integration with PCs and PLCs for streamlined system development across a range of applications.

How to Select the Right Large Volume Syringe Pump

Assessing Your Application Needs

Choosing the correct pump starts with a clear understanding of your application’s requirements. Key parameters to consider include:

-

Flow Rate: What is the minimum and maximum flow rate needed?

-

Total Volume: How much fluid needs to be dispensed in a single run?

-

Fluid Properties: What is the viscosity of the fluid? Is it chemically aggressive?

-

Pressure: Will the pump need to overcome significant back pressure?

A major advantage of Chemyx pumps is that they are syringe-agnostic, meaning they are compatible with a vast range of syringe materials, brands, and sizes, offering users maximum flexibility. You can compare different models based on specifications like force, flow rate, and syringe size to find the optimal fit.

Exploring Chemyx Solutions for Large Volumes

For applications that require a large volume syringe pump, Chemyx offers several powerful solutions. The HP6 is an excellent choice, with models capable of holding syringes up to 1L and generating immense linear force to handle large volumes and viscous fluids with ease. The HP series (HP1, HP6, HP6-CF) is ideal for applications requiring both large volumes and ultra-high pressure. For multi-channel applications, accessories like the 4-syringe expansion rack for the Fusion 6000X allow for parallel dispensing, significantly increasing throughput.

Comparing Market Alternatives

While the market includes large volume pumps primarily designed for medical settings, such as the B. Braun Infusomat® [2] and the Baxter Novum IQ [3], it is crucial to select a pump designed for the intended application. Chemyx syringe pumps are engineered specifically for industrial and research use. Key differentiators include their robust, all-metal construction, the flexibility of using removable syringes of any type, and direct access to an experienced engineering support team—advantages not typically found with pumps designed for clinical environments.

The Chemyx Advantage: Precision, Durability, and Support

Chemyx is the preferred choice for industrial programmable syringe pumps due to a proven combination of precision, durability, and versatility. With a track record validated by over 20,000 scientific citations, our pumps deliver the reliable performance that researchers and engineers need. The durable construction ensures longevity in industrial environments, while advanced programmability provides the flexibility to automate even the most complex fluidic tasks.

Chemyx is committed to serving all levels of research and industry, also offering specialty quotes for projects with budget constraints. To find the perfect syringe pump for your specific application, leverage the expertise and technological advancements of Chemyx Inc. Contact the customer care team of experienced engineers today to discuss your requirements at info@chemyx.com.