In the demanding world of pharmaceutical research, where a single misplaced microliter can invalidate months of work, precision is not a luxury—it is the foundation of discovery. The programmable syringe pump is an indispensable instrument that provides the exactitude required for critical fluid handling during pharmaceutical development. These devices offer unparalleled, automated control over the infusion (pushing) and withdrawal (pulling) of fluids during fluid handling techniques, transforming manual processes prone to error into models of consistency. This automation improves experimental consistency, enhances data reliability, and frees up valuable researcher time. In fields like drug discovery and development, where even the slightest inconsistency can compromise results, Programmable Syringe Pumps: Top Precision for Labs are a transformative investment.

Topics Covered:

- The Critical Role of Precision in Pharmaceutical Research

- Key Applications of Programmable Syringe Pumps in Pharma Research

- Selecting the Right Programmable Syringe Pump for Pharmaceutical Labs

- Investing in Precision for Advanced Pharmaceutical Research

The Critical Role of Precision in Pharmaceutical Research

Pharmaceutical research relies on accurate, repeatable experiments to develop safe and effective drugs. Programmable syringe pumps are fundamental to achieving the level of precision that modern science demands.

Ensuring Accuracy and Reproducibility

Reliable scientific conclusions are built on reproducible experiments. A programmable syringe pump eliminates variables by delivering the exact same volume at the exact same rate, every single time. This consistency is vital for the sensitive chemical and biological analyses common in pharmaceutical development, ensuring that results are a true reflection of the experiment, not procedural error. The importance of syringe pumps in scientific research labs is therefore central to generating valid data.

Achieving Pulseless Flow for Sensitive Assays

For many pharmaceutical applications, a smooth, continuous stream of liquid is necessary for accurate results. A pulseless flow is critical in techniques like mass spectrometry, where pulsations can create signal noise and interfere with precise measurements. It is also essential in microfluidics for drug screening, where an unstable flow can disrupt delicate cell structures or droplet formation. The ability to deliver a stable, pulseless flow is a key advantage of using precision syringe pumps in biopharmaceutical drug development [1].

Key Applications of Programmable Syringe Pumps in Pharma Research

Programmable syringe pumps are versatile tools used across the entire pharmaceutical research pipeline, from initial drug discovery to preclinical testing.

Drug Discovery and High-Throughput Screening (HTS)

In high-throughput screening, researchers test thousands of compounds to identify potential drug candidates. Programmable syringe pumps automate the precise delivery of these compounds to microplates, accelerating the screening process. This automation allows research teams to test vast libraries of compounds with high efficiency and accuracy, significantly increasing the chances of finding a promising lead.

Formulation Development and Drug Delivery Studies

Programmable pumps are crucial for studying how different drug formulations release active ingredients over time. They simulate physiological conditions to help develop and test controlled-release and extended-release drug delivery systems. This research is essential for creating more effective medicines with fewer side effects, often involving advanced tools like implantable micro-infusion pumps for in-depth studies [2].

Preclinical Studies and In Vivo Models

Syringe pumps are widely used for continuous, long-term intravenous drug delivery in free-moving animal models like rats and mice. This method is critical for pharmacokinetics (PK) and pharmacodynamics (PD) studies, which analyze how a drug is absorbed, distributed, metabolized, and excreted in a living system. Following established protocols for continuous drug delivery is vital for accurately assessing a drug’s efficacy and safety profile [3].

Important Note: Chemyx syringe pumps are designed for laboratory research and are not for use in humans.

Analytical Chemistry and Quality Control

The reliability of data from analytical instruments like High-Performance Liquid Chromatography (HPLC) and Mass Spectrometry (MS) depends on precise sample introduction. Syringe pumps ensure that samples and standards are fed into these systems with exceptional accuracy. This guarantees the integrity of data used for compound identification, purity analysis, and quality control. Understanding what is a syringe pump highlights its foundational role in analytical rigor.

Selecting the Right Programmable Syringe Pump for Pharmaceutical Labs

Selecting the right pump requires matching its technical specifications to your specific experimental needs to ensure optimal performance and results.

Key Features to Evaluate

-

Flow Rate Range and Accuracy: Choose a pump that operates accurately within your required flow rate range, from nanoliters to milliliters per minute, to match the scale of your application.

-

Programmability and Control: For complex workflows, select a pump that supports multi-step programs (e.g., infuse, pause, withdraw). Modern control options like touchscreens and connectivity ports (USB, RS232) allow for easy integration with other lab equipment and automation systems [4].

-

Infusion and Withdrawal Capability: Dual functionality offers greater versatility for tasks such as serial dilutions, gradient formation, or mixing reagents within the syringe.

-

Build Quality and Chemical Compatibility: Ensure the pump is constructed from durable, chemically resistant materials to withstand the laboratory environment and prevent sample contamination.

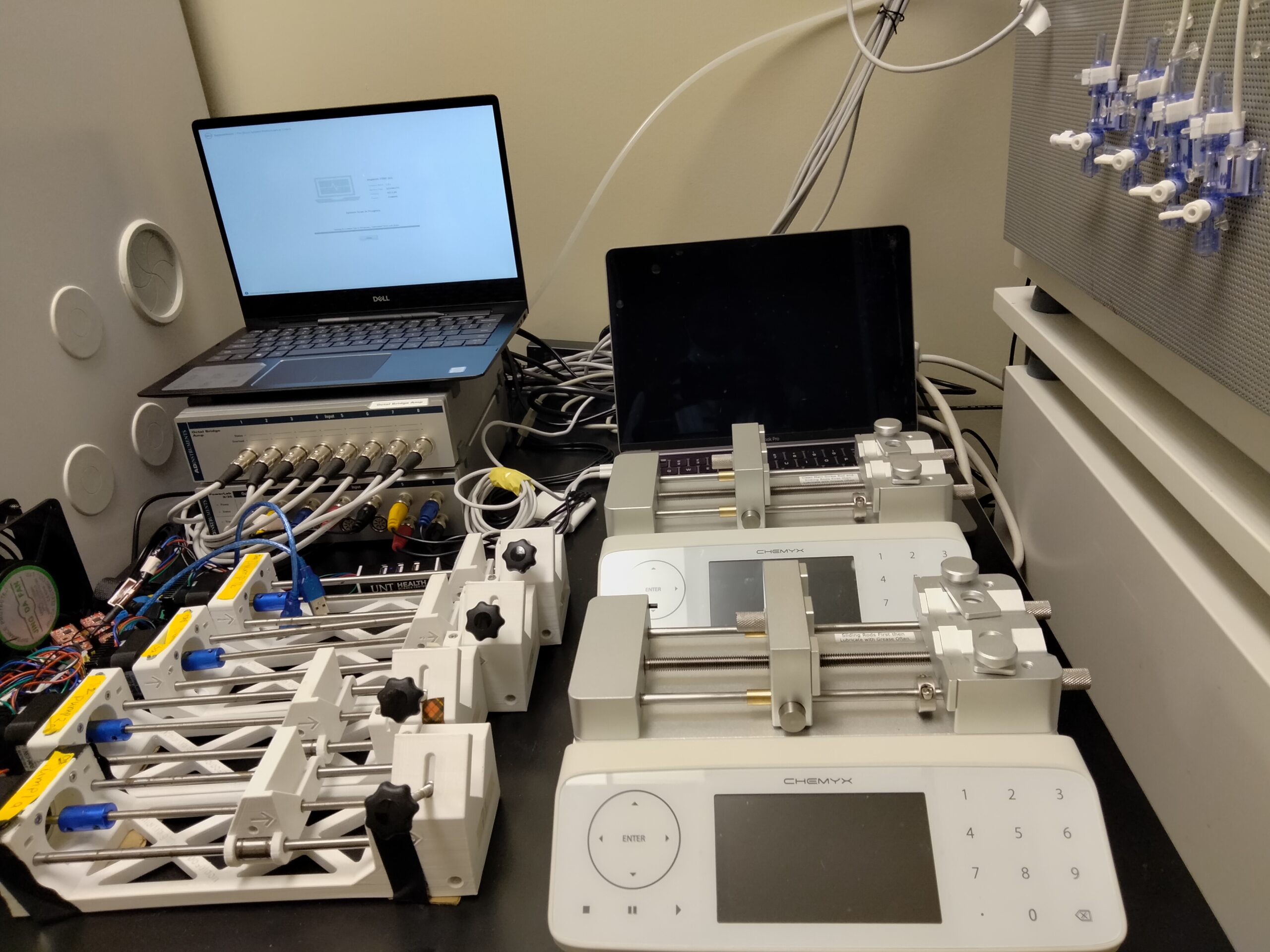

Case Study: Chemyx Pumps in Pharmaceutical Applications

The application of Chemyx syringe pumps in cutting-edge research demonstrates their reliability and precision in demanding pharmaceutical environments.

-

mRNA Vaccine Development: Researchers at MIT utilized a Chemyx Fusion 4000 syringe pump for lipid nanoparticle (LNP) synthesis in a microfluidic device. The pump’s precise, independent control over the ethanol and aqueous phases was essential for creating the delivery vehicle for mRNA vaccines.

-

Glaucoma Research: At Indiana University, the Chemyx Fusion-200X is used in eye perfusion systems to study glaucoma pathogenesis. The pump’s ability to maintain stable flow rates is crucial for regulating intraocular pressure and investigating disease mechanisms.

-

Double Emulsion Generation: A researcher developing advanced drug delivery systems used the Chemyx Fusion 4000’s independent channels to control flow rates for creating double emulsion droplets, a key technique in modern encapsulation technology.

Conclusion: Investing in Precision for Advanced Pharmaceutical Research

A high-performance programmable syringe pump is a critical investment that directly impacts the quality, efficiency, and success of pharmaceutical research. Its key benefits—unparalleled accuracy, automation of complex workflows, and enhanced data reproducibility—are essential for driving innovation.

As a trusted leader in the industry, Chemyx Inc. offers a comprehensive portfolio of high-performance syringe pumps backed by thousands of scientific citations. Explore our range of solutions to find the perfect instrument to accelerate your discovery and elevate your research.