In this article, the following sections will be explained:

- Advanced Microfluidic Technologies for Laboratory Applications

- Critical Performance Parameters for Biotech Fluid Control

- System Integration & Automation Capabilities

- Industry Applications and Compliance Standards

- Specialized Components & Accessories

- Emerging Technologies & Future Trends

Advanced Microfluidic Technologies for Laboratory Applications

Precision Syringe Pump Innovations

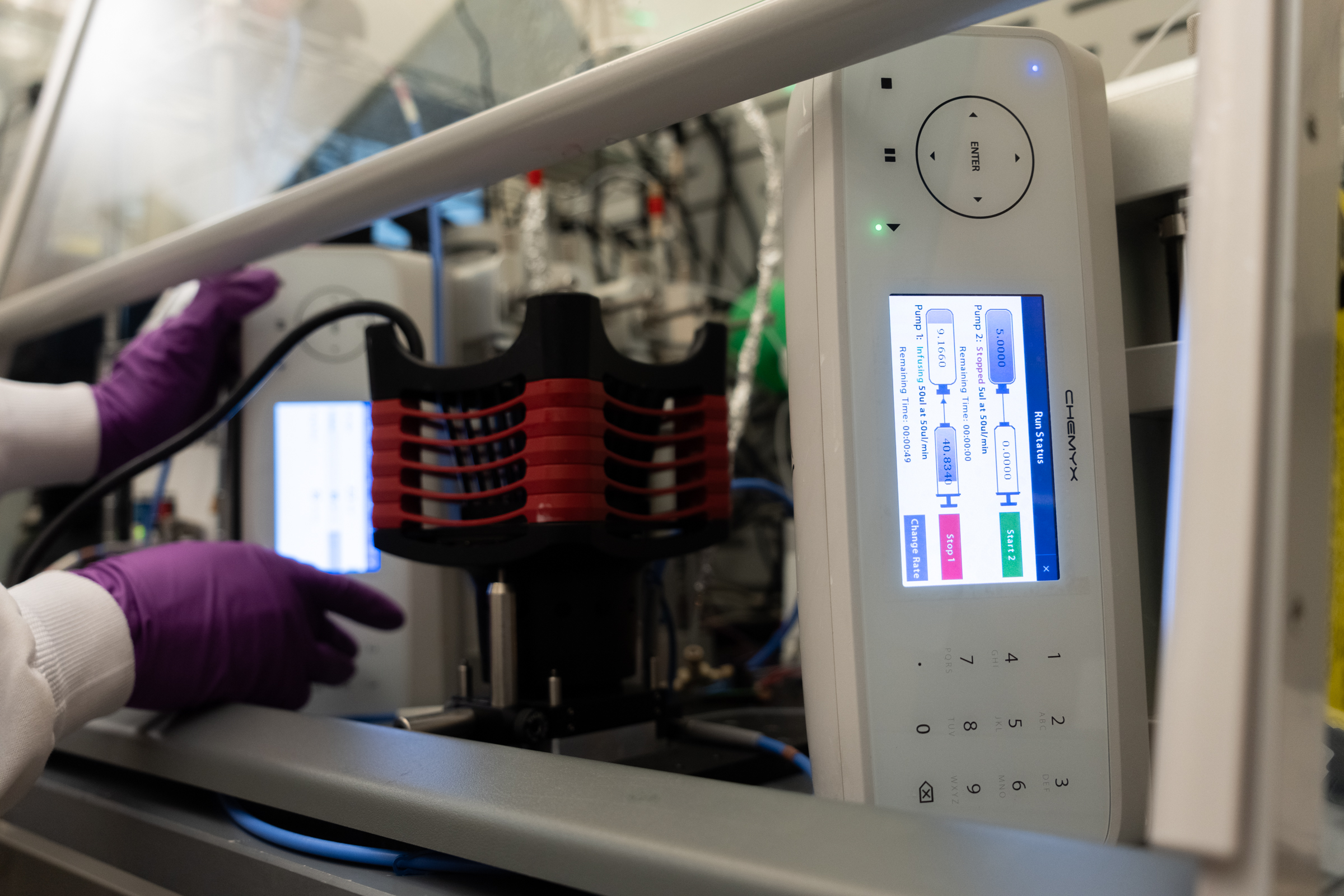

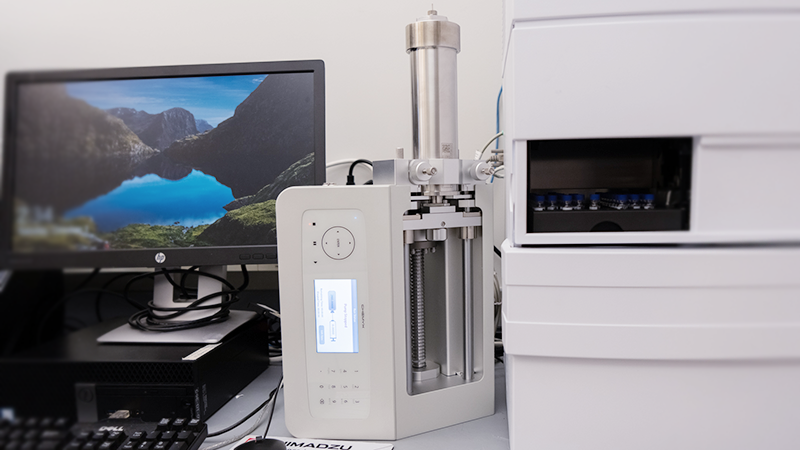

The evolution of programmable precision syringe pumps has fundamentally transformed fluid control systems for biotech research. These sophisticated instruments are meticulously engineered to provide the unparalleled accuracy and reproducibility essential for sensitive biological experiments. Chemyx Inc, a leading manufacturer, has pioneered innovations in this critical domain, developing systems that are indispensable for modern biotechnological endeavors. Modern precision syringe pumps are designed to achieve sub-microliter volume delivery with minimal pulsation, a critical performance parameter in applications sensitive to flow dynamics, such as cell perfusion, drug delivery, and microfluidic assays.

Achieving consistent sub-microliter delivery with minimal pulsation necessitates stringent design and manufacturing protocols. Chemyx Inc’s syringe pump systems are engineered to maintain exceptional accuracy specifications, typically achieving a volumetric accuracy of ± < 0.35%. This high degree of volumetric control is essential for ensuring the integrity and reproducibility of experimental results in critical biotech applications. For instance, in drug discovery and molecular analysis, precise reagent addition directly influences reaction kinetics and product yield, making these fluid control systems for biotech a cornerstone of reliable research. The widespread adoption of Chemyx systems is evidenced by over 20,000 citations in research applications, underscoring their proven reliability and performance across diverse scientific investigations.

Multi-Channel Infusion and Withdrawal Systems

Advanced fluid control systems for biotech often incorporate multi-channel capabilities, enabling the precise and intricate execution of complex liquid handling procedures. These systems feature independent motor control for each channel, facilitating simultaneous infusion and withdrawal at precisely controlled rates. A prime example of this technology is the Chemyx Fusion 4000X Multi-Channel Infusion & Withdrawal Syringe Pump, which offers advanced features such as programmable ramping rate control and oscillatory cycle modes.

The operational versatility of these multi-channel fluid control systems for biotech is demonstrated by their broad flow rate capabilities, which can range from 0.0001 µL/min to 170.5 mL/min, accommodating various syringe sizes. This adaptability supports a wide array of experimental protocols, from micro-perfusion in organ-on-chip models to continuous media exchange in bioreactors. Key operational features include:

-

Independent control over each fluid channel, allowing for synchronous or asynchronous operations.

-

Precise programming of infusion and withdrawal rates to maintain dynamic fluid environments.

-

Programmable oscillatory modes, ideal for mimicking pulsatile physiological conditions or inducing mixing.

-

Capability for complex ramping protocols to gradually adjust flow rates over time.

Critical Performance Parameters in Biotech Fluid Control

Accuracy and Precision Standards

In microfluidic applications, a clear distinction between accuracy and precision is paramount for the rigorous evaluation of fluid control systems for biotech. Accuracy quantifies the proximity of a measured value to its true value, while precision denotes the reproducibility of repeated measurements under identical conditions. Both are indispensable for obtaining reliable and verifiable experimental data in biotechnological research.

International standards, such as ISO/TS 6417 and IEC 60601-2-24 (relevant for medical electrical equipment, including infusion pumps), establish benchmarks for flow rate accuracy in various applications, profoundly influencing the design and validation of high-performance fluid control systems. Adherence to these standards ensures that devices meet the demanding requirements of biotechnological research and clinical applications where applicable. Furthermore, proper volume usage is directly correlated with minimizing error rates in experimental procedures. Operating syringe pumps within the middle range of their capacity typically optimizes performance and reduces volumetric errors, which can become disproportionately significant at the extreme ends of the syringe volume range. For a comprehensive understanding of these crucial distinctions, refer to the Microfluidic Pump Accuracy- Precision Specs That Matter knowledge base article. Maintaining accuracy across the entire operational range is paramount for robust experimental design and data integrity.

Flow Rate Control and Pulsation Management

Pulsation-free delivery is a critical requirement in sensitive biotech applications. Excessive pulsation can induce shear stress on delicate biological samples, disrupt laminar flow profiles in microfluidic channels, and compromise detector stability in analytical instruments. While various actuation methods exist, including piezoelectric and peristaltic systems, syringe pumps, such as those offered by Chemyx Inc, are frequently favored for their inherent ability to deliver continuous, low-pulsation flow due to their positive displacement mechanism.

Effective fluid control systems for biotech must also address back pressure considerations and dead volume minimization. Elevated back pressure can destabilize flow, lead to cavitation, and potentially damage sensitive components or biological samples. Conversely, excessive dead volume can result in sample dilution, prolonged washout times, and compromised experimental kinetics, particularly in fast-reacting systems. High Precision Microfluidic Pump Solutions for Research are specifically designed to mitigate these issues, ensuring stable and reliable fluid delivery even under demanding conditions. The precise control offered by Chemyx systems is indispensable in areas such as drug discovery and cell biology, where consistent and stable fluid delivery rates are essential for experimental reproducibility and validity.

System Integration and Automation Capabilities

Laboratory Automation Interfaces

Modern fluid control systems for biotech are engineered for seamless integration into existing laboratory automation platforms. These systems typically offer a robust suite of connectivity options, including USB, RS232, and TTL interfaces, enabling reliable communication with external control systems and laboratory information management systems (LIMS). The Chemyx Fusion 100X: Laboratory Syringe Pump – Dual Channel exemplifies such integration, featuring intuitive touchscreen control systems and highly programmable operation modes that enhance user interaction and experimental flexibility.

Compatibility with powerful programming environments like LabVIEW and MATLAB facilitates the development of sophisticated automated workflows, which are essential for high-throughput research, process control, and complex experimental designs. This capability allows researchers to implement custom control algorithms and automated experimental protocols, thereby enhancing efficiency, minimizing manual errors, and ensuring precise control over fluid delivery parameters. Chemyx Inc.’s systems often include free programmable modes and are backed by a comprehensive 2-year limited warranty coverage, ensuring long-term operational reliability and peace of mind for researchers.

Hardware Components and Build Quality

The reliability and accuracy of fluid control systems for biotech are fundamentally dependent on the quality and precision of their underlying hardware components. These include robust drive mechanisms, such as stepper, servo, and DC motors, which are carefully selected for their torque, speed, and precision characteristics. Lead screw assemblies, syringe holders, and plunger clamps are manufactured to exacting tolerances to ensure consistent and accurate fluid delivery, minimizing mechanical backlash and maximizing linear motion fidelity.

Advanced control systems integrate sophisticated sensor feedback mechanisms that continuously monitor performance and allow for real-time adjustments, ensuring that programmed flow rates are maintained even against dynamic changes in system conditions. These feedback loops are crucial for maintaining consistency and accuracy in critical experiments. The importance of proper system selection for specific laboratory applications cannot be overstated; matching system capabilities to precise experimental requirements is critical for achieving optimal results. Guidance on selecting the appropriate pump and syringe can be found in the Which Syringe Pump and Type of Syringe is Right for My Lab resource. Furthermore, superior build quality encompasses meticulous material compatibility, exceptional mechanical durability, and thermal stability to ensure consistent performance across diverse experimental environments.

Industry Applications and Compliance Standards

Biotech and Pharmaceutical Research Applications

Precision fluid control systems for biotech are extensively utilized in the development of cutting-edge drug delivery systems and in pioneering molecular discovery research. These indispensable tools are deployed across national laboratories, leading universities, and global pharmaceutical companies. They are integral to critical processes within chemical, pharmaceutical, and biotech research and development (R&D) environments, where precision, reliability, and reproducibility are paramount for both fundamental scientific inquiry and accelerated product innovation.

Compliance with international standards such as CE, RoHS, REACH, and FCC regulations is mandatory for these systems. These certifications ensure that devices adhere to stringent environmental protection, safety, and electromagnetic compatibility requirements, enabling safe and compliant operation in professional laboratory settings. It is crucial to note that Chemyx Inc. syringe pumps are designed and optimized for non-medical laboratory use, and users must strictly adhere to established safety protocols and regulatory guidelines for their specific applications.

Environmental and Analytical Applications

Beyond traditional biotech laboratories, next-generation environmental monitoring applications are increasingly leveraging advanced fluid control systems for biotech technologies. This includes portable analyzer systems with real-time diagnostic capabilities that demand robust fluid control systems capable of maintaining exceptional precision even under challenging field conditions [1].

Applications in water testing and soil remediation require fluid control systems capable of accurately handling complex and often particle-laden sample matrices while preserving measurement accuracy. The ongoing global shift toward compact, portable environmental testing devices is a key driver for innovation in miniaturized fluid control technology. These devices aim to deliver laboratory-grade precision in field-deployable formats, enabling rapid and on-site environmental assessments and contributing to more efficient and timely data collection.

Specialized Components and Accessories

Fluidic System Components

The integrity and optimal performance of fluid control systems for biotech are highly dependent on the quality and appropriate selection of all fluidic system components. Proper selection of hose barb fittings and connection systems is critical for ensuring leak-free operation throughout the entire fluidic path. For example, a 1/8 NPT to 3/16 Hose Barb Fitting is specifically engineered for robust, reliable fluidic connections in demanding applications.

The importance of appropriate fitting selection extends to material compatibility with diverse reagents, suitability for specific pressure ratings, and ease of maintenance and replacement. High-quality, chemically resistant fittings contribute significantly to overall system reliability and measurement accuracy by eliminating potential sources of leakage, contamination, or flow disruption. Pricing considerations and procurement options for specialized components should always factor in the long-term cost of ownership, including potential replacement intervals and the critical impact of component malfunction on experimental integrity.

Degassing and Flow Monitoring Solutions

Inline degassing plays a crucial role in precision liquid analysis within fluid control systems for biotech by actively removing dissolved gases. These dissolved gases can form bubbles, which disrupt precise flow patterns, introduce measurement artifacts, and interfere with sensitive detectors, particularly in HPLC and microfluidic applications. Degassing systems often incorporate specialized membranes and vacuum chambers to continuously and efficiently remove these dissolved gases.

Flow monitoring capabilities significantly enhance system performance by providing real-time measurement of actual flow rates and delivered volumes. These advanced monitoring systems enable closed-loop control, which automatically adjusts pump parameters to maintain programmed delivery rates despite minor variations in system conditions, thus ensuring unparalleled consistency. Comprehensive fluid management solutions, offered by specialized providers like Biotech Fluidics, include a range of separation tools and flow components meticulously tailored for diverse application requirements [2]. Additionally, HPLC pump validation solutions are available for performance verification in highly regulated environments.

Emerging Technologies and Future Trends

Next-Generation Environmental Applications

Advancements in microfluidic environmental analysis systems are enabling unprecedented real-time monitoring capabilities, fundamentally transforming our approach to environmental assessment. Innovations such as drone-mounted diagnostic capabilities are expanding monitoring coverage to remote and previously inaccessible locations, aiming to deliver laboratory-quality measurements in challenging environments [3].