Microfluidic pump systems and microfluidic solutions require precise and accurate flow control mechanisms to achieve repeatable, reproducible experimental results for research in biotech, pharmaceuticals, and gas & oil applications. Critical accuracy specifications determine a system’s performance and reliability across various laboratory techniques and protocols, with precision parameters impacting experimental validity directly.

The following sections are covered in this article:

- Critical Performance Parameters for Microfluidic Systems

- Syringe Pump Technology Analysis

- Application-Specific Requirements

- Environmental and Operational Factors

- System Optimization Parameters

- Quality Assurance Standards

Critical Performance Parameters for Microfluidic Systems

International Standards Framework

The ISO/TS 6417 establishes standardized requirements for all commercial and clinical microfluidic pumps symbols and performance communications [1], providing the standards and comprehensive guidelines for microfluidic pump solutions. IEC 60601-2-24 third edition defines criteria for measuring flow rate accuracy of clinical drug infusion pumps used in certified agencies and hospitals [2].

International standards specify maximum permissible flow rate errors of ±5%, with ISO standard 7886-2 establishing requirements for syringes used with power-driven syringe pumps [3][4]. The revised ISO 7886-2:2020 standard incorporates measurement uncertainty concepts and references EURAMET Calibration Guide 19 for [5].

Accuracy Specifications Across Technologies

Research demonstrates measurable differences in pump accuracy across technologies. Comparative studies document syringe pumps achieving approximately 2% error rates with coefficients of variation below 1% at all tested flow rates [6][7]. Mean percent error ranges from 1.4% to 18.6% despite manufacturer specifications of ±5% accuracy [8].

Volume measurements using syringes require at least 20% of maximum syringe volume, with medical applications requiring 50% minimum capacity usage [3]. Studies demonstrate increased likelihood of unacceptable error (>5%) when measuring below 20% of labeled syringe capacity [8].

Chemyx syringe pumps for microfluidic applications in research address these limitations through precision engineering that maintains accuracy across the full operational range. The Chemyx Fusion series are precision syringe pumps that incorporate mechanical design elements that minimize dead volume effects and optimize measurement precision at low flow rates commonly required in microfluidic applications.

Syringe Pump Technology Analysis

Mechanical Precision Systems

Syringe pumps function as the standard for metabolic research and infusion studies due to superior accuracy and precision compared to alternative pump technologies [6][7]. Syringe pumps provide precise control over fluid movement and delivery across diverse experimental configurations [3].

High-precision syringe pumps utilize machined lead screws with stepper motors based on clock systems accurate to seconds over years [4]. Lead screw pitch and stepper motor speed remain constant over operational lifespans, eliminating requirements for annual accuracy calibration [4].

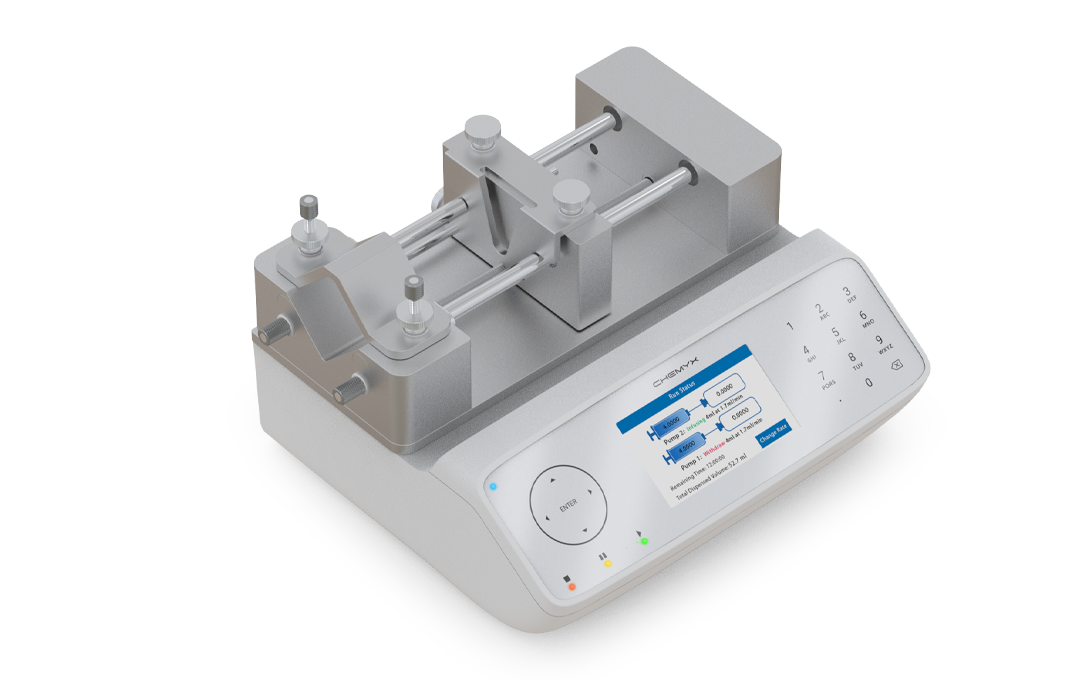

The Chemyx Fusion 4000X incorporates dual independent drive systems that enable complex liquid handling procedures including ramping rates, push-pull operations, oscillatory cycles, and continuous flow profiles. This multi-channel architecture provides researchers with simultaneous control of multiple fluid streams while maintaining individual accuracy specifications for each channel.

Performance Validation Methods

Trumpet curves constructed using IEC 60601-2-24 specifications provide accurate flow rate representation by plotting minimum and maximum accuracy values against analysis periods [2]. Comparison methods using Infusion Device Analyzers (IDA) to generate reference flow rates produce errors exceeding manufacturer specifications at low flow rates [5].

Research demonstrates both syringe and peristaltic pumps achieve high accuracy and precision across flow rate ranges, with in vivo substrate kinetics assessments showing equivalent performance [7]. However, microfluidic pump solutions require evaluation under application-specific conditions to determine optimal performance parameters.

It is easy to verify the accuracy of a Chemyx syringe pump by using a high-quality, small glass syringe, such as a Hamilton Glass Syringe, that fits the syringe pump model, filled with degassed distilled water to measure and verify the accuracy of your Chemyx syringe pump.

Application-Specific Requirements

Biomedical Research Applications

Intravenous drug infusions in critically ill patients require accurate syringe infusion pumps, particularly during transportation where altitude influences device performance [9][10][11]. High-risk medications require precise flow rates due to narrow therapeutic margins, especially for drugs administered to newborn children requiring low flow rates [5].

Chemyx syringe pumps are not for intravenous infusions in humans. However, Chemyx systems incorporate pressure monitoring technology and software that maintain user-defined pressure throughout withdrawal or infusion processes in biomedical research techniques. The heated syringe capabilities provide consistent results by reducing temperature and viscosity variations that affect flow accuracy in biomedical applications.

Chemical Development Integration

Laboratory syringe pumps perform critical functions in chemical development, transforming raw chemicals and bioactive molecules into consumer products including complex materials, medicine, and food products . Microfluidic syringe pumps manipulating small fluid volumes contribute to innovation across research applications .

Positive displacement pumps like syringe pumps represent the preferred choice for chemical engineering techniques, operating efficiently with high-viscosity materials at low flow rates . Continuous microinfusion at micrometer levels avoids experimental variation and side reactions while supporting higher-quality product creation .

The Chemyx Fusion 6000X can deliver up to 700 lb linear pushing force, specifically engineered for dosing viscous solutions against back pressure with microfluidic precision. High-tensile-strength, hardened-steel guide mechanisms with machined metal holders enable high-load operation while ensuring precise microflow dosing, which is perfect for novel material development.

Environmental and Operational Factors

Altitude and Environmental Effects

Environmental factors including altitude affect pump performance, with starting times increasing at higher elevations and cycle times being higher at increased altitudes [10]. Altitude changes significantly impact device accuracy, with systems showing decreased median flow rates and increased variability ranges at higher elevations [11].

Accuracy varies depending on measurement methods and alignment with IEC 60601-2-24 standards for clinical applications [10][11]. Standard weight measurement methods demonstrate devices complying with manufacturer requirements, with delivered flow rates consistent with programmed rates [10].

Temperature and humidity also affect syringe pump performance. Chemyx recommends utilizing Chemyx syringe pumps in the environments in the table below:

| Operating Temperature | 4°C to 40°C (40°F to 104°F) |

|---|---|

| Storage Temperature | -10°C to 70°C (14°F to 158°F) |

| Humidity | 20% to 80% RH, non-condensing |

System Optimization Parameters

Measurement system accuracy equals that of the least accurate element, requiring understanding of potential error sources for optimal syringe pump selection [3]. Optimal syringe selection involves choosing sizes where measured volumes occupy the highest percentage of nominal capacity to improve precision and volume accuracy [3].

Chemyx precision machining with metal components ensures accuracy levels required for microflow applications while providing chemical resistance and mechanical durability. The all-glass touchscreen interface and machined metal design provide chemical resistance and superior durability for diverse laboratory environments.

Quality Assurance Standards

Calibration and Validation Requirements

Metrological requirements address water density calculations, evaporation and buoyancy corrections, ambient conditions specifications, instrument thermostabilization, and equipment specifications [5]. Best metrology practices for calibrating infusion devices led to ISO 7886-2 standard revision [5].

The US FDA recognition of ISO 7886-2:1996 was superseded by ISO 7886-2:2020, with premarket submissions requiring conformity to the revised standard following a transition period ending in July 2021 [5]. These standards help manufacturers safeguard reliable operation of infusion devices in hospitals and reduce risks of adverse patient incidents [5].

Performance Validation Protocols

Modern microfluidic pump solutions require comprehensive validation protocols that address system-specific performance characteristics. Chemyx provides customer and calibration support, extensive technical documentation, and syringe pump information to ensure optimal system configuration and validation.

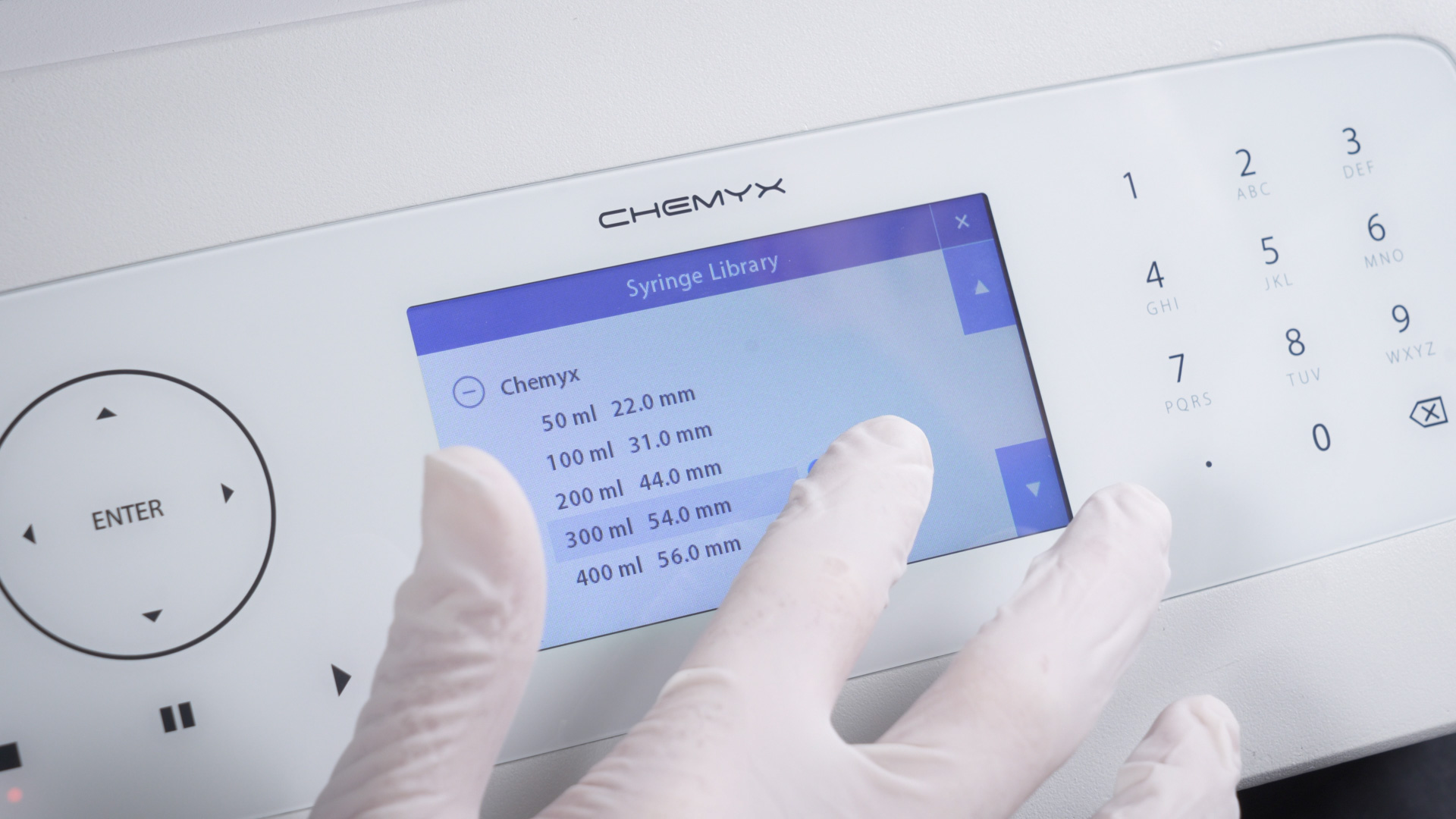

Chemyx’s Fusion precision series incorporates intuitive software that enables users to program and customize flow profiles with robust databases of brand-name syringes. Remote computer control capabilities through USB, TTL, and RS232 communication connections provide integration flexibility for fully automated systems.

Selection Criteria for Microfluidic Pump Solutions

Optimal microfluidic pump solutions selection requires evaluation of application-specific requirements, flow rate ranges, accuracy specifications, and environmental operational conditions. System performance depends on matching pump capabilities with experimental protocols and validation requirements.

For dual-channel control applications, the Chemyx Fusion 4000X provides independent motor systems with flexible programming capabilities. High-pressure applications benefit from Fusion 6000X engineering designed for viscous fluid handling under challenging conditions.

Advanced microfluidic applications require precision engineering and comprehensive technical support. Chemyx manufacturing processes incorporate quality control measures that ensure consistent performance across production batches, with comprehensive warranty coverage supporting long-term operational reliability.

Contact Chemyx Inc at info@chemyx.com for technical consultation regarding optimal microfluidic pump solutions for specific research applications. Chemyx’s engineering team provides detailed system specifications and application guidance to ensure optimal performance for demanding laboratory protocols.