In this article, we’ll take a scientific and methodical approach to help you determine the best syringe pumps for specific microfluidic applications in research.

The following sections are covered in this article:

- Hypothesis, Methods, and Terminology

- Understanding Microfluidic Pumping Mechanisms

- Critical Performance Parameters

- Application-Specific Requirements

- Selection Criteria for Microfluidic Pump Solutions

- Advanced Integration Considerations & Pump Selection Checklist

- Frequently Asked Questions

Hypothesis/Question: How do researchers effectively select high-precision microfluidic pump solutions to ensure a reliable experimental outcomes across diverse applications?

Method & Data: This article synthesizes current research findings on microfluidic pumping mechanisms, critical performance parameters, and application-specific requirements, drawing upon authoritative scientific literature and industry specifications.

So, what are we talking about when we say “microfluidic pump solutions”? Simply put, these are highly specialized devices that let scientists and researchers precisely control incredibly tiny amounts of liquid – think drops smaller than a grain of sand! Why does this matter? Well, in fields like drug discovery or cell biology, handling minute volumes with pinpoint accuracy is absolutely crucial for getting reliable, repeatable results.

Microfluidic pump solutions are essential for fluid control in modern laboratory research. These devices manipulate minute fluid volumes with accuracy, supporting advancements in fields like drug discovery, cell biology, and analytical chemistry. For consistent, verifiable experimental outcomes, Chemyx provides precision fluid control instrumentation.

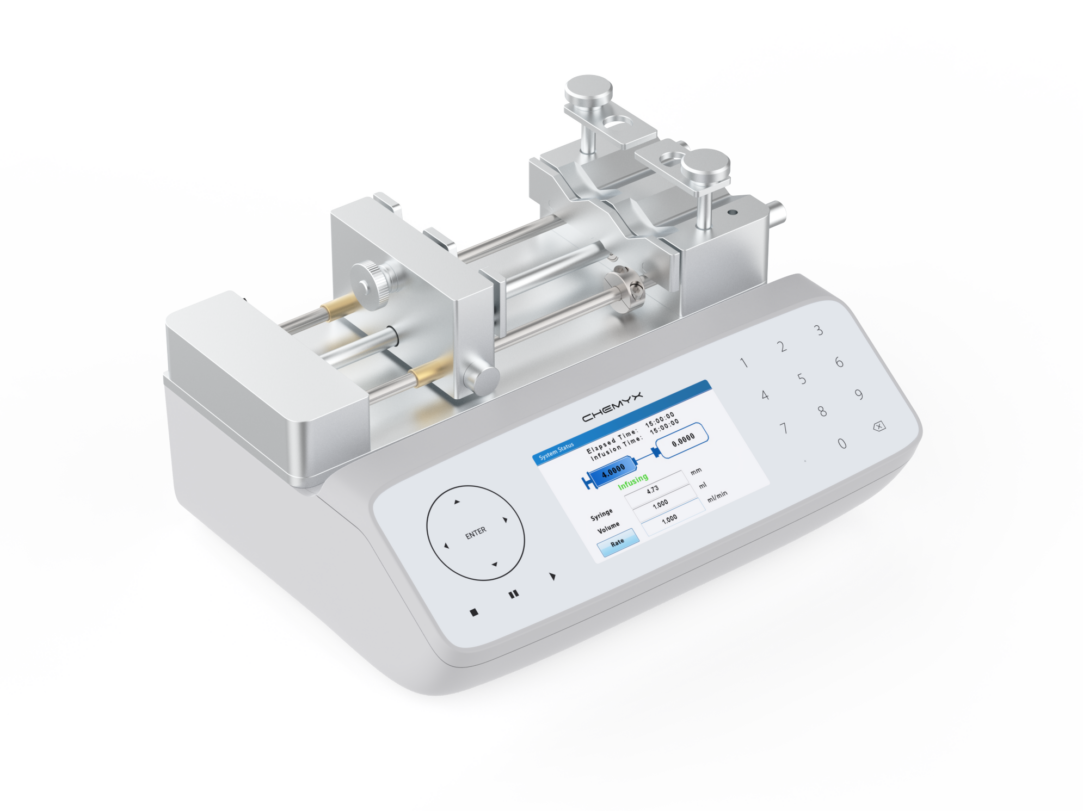

The control required for microfluidic applications necessitates pump technologies capable of delivering sub-microliter volumes with minimal pulsation and repeatability. Chemyx provides programmable syringe pumps designed to meet these requirements across research, biotech, pharmaceutical, and industrial applications, contributing to consistent research outcomes.

A Quick Look at Key Terms:

Before we dive deeper, let’s clarify a few things. You’ll likely hear these terms often in the world of microfluidics:

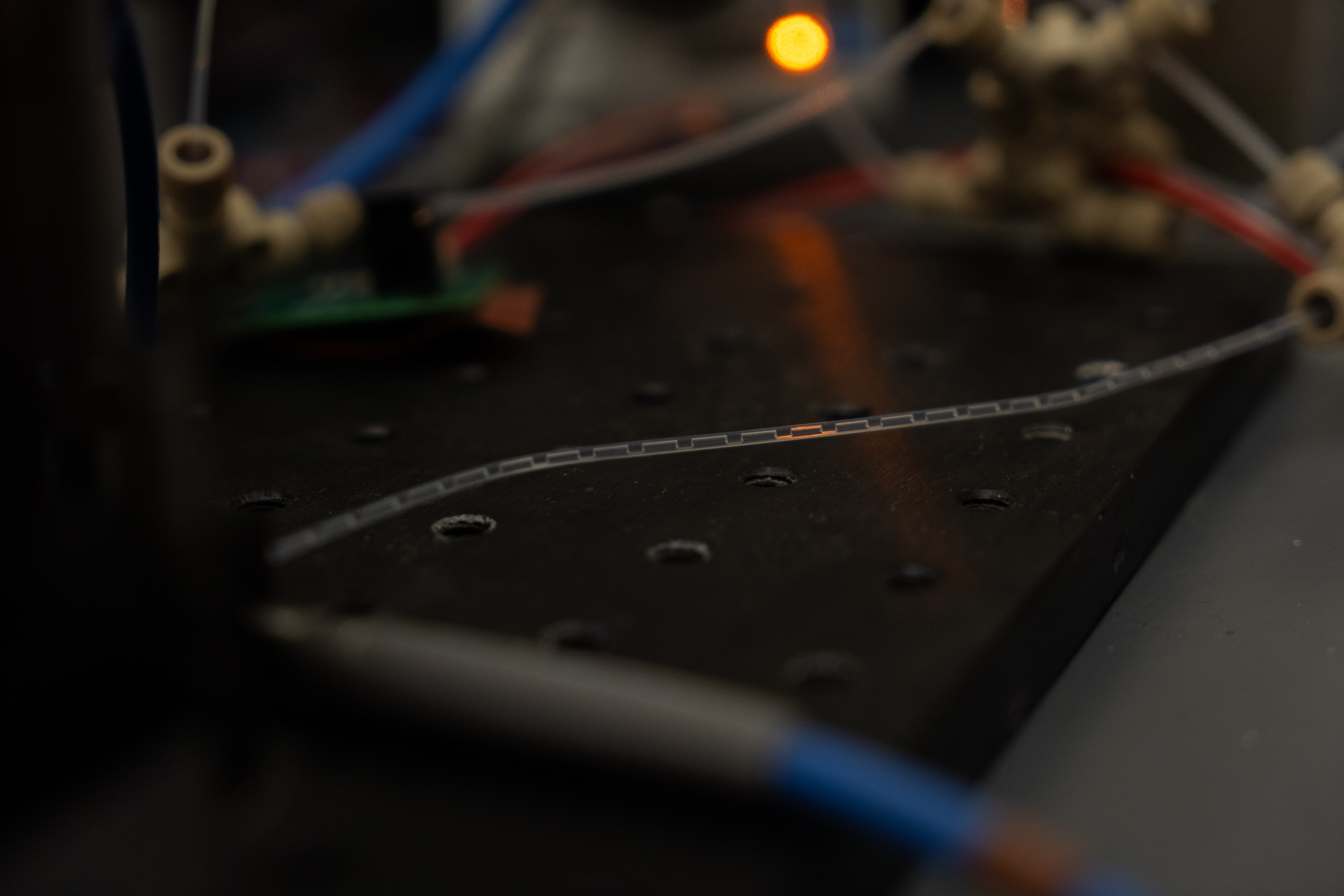

- Microfluidics: The science and technology of manipulating and controlling fluids (typically in the nanoliter to picoliter range) in channels with dimensions of tens to hundreds of micrometers.

- Pulsation: Uneven, fluctuating flow. In microfluidics, consistent, non-pulsatile flow is often desired for stable experimental conditions.

- Dead Volume: The volume of liquid that remains in the pump, tubing, or system after a dispense cycle and isn’t delivered to the sample or device. Minimizing this is crucial for expensive or rare reagents.

- Back Pressure: The resistance or opposing force a fluid experiences as it moves through a system (e.g., through narrow channels, filters, or against other liquids). Pumps need to overcome this to maintain flow.

- Flow Rate: The volume of fluid moved per unit of time (e.g., microliters per minute). Precision in flow rate is vital for controlled experiments.

Understanding Microfluidic Pumping Mechanisms

Microfluidic pump solutions employ various actuation methods, each offering distinct advantages. Piezoelectric actuation provides control but can generate pulsatile flow. Combined actuation methods, leveraging both piezoelectric effects and liquid crystal backflow, have achieved a maximum flow rate of 4.494 µL/min [1].

Alternatively, peristaltic micropumps, driven by magnetic actuation, offer linear flow rates of approximately 490 µL/min with maximum back pressures of 592 Pa [2]. These systems can help minimize contamination risks because the pump mechanism does not directly contact the fluid.

Electroosmotic pumps are advantageous when low power consumption is important. For instance, CMOS-based traveling-wave electroosmosis pumps operate at 1.5V with a power consumption of only 1.74mW, and achieve flow rates of 51 µm/s for diluted serum applications [3].

Critical Performance Parameters

When you’re evaluating microfluidic pump solutions, you’ll need to pay close attention to a few key specifications. These details are often pivotal for the success of your experiments.

Flow Rate Precision

Microfluidic applications involve flow rates ranging from nanoliters to milliliters per minute. All-glass microfluidic pumps have demonstrated volumetric outputs of 0.5–0.7 nL/s under pump head pressures of 300 Pa [4]. For higher throughput needs, 3D-printed centrifugal pumps can achieve maximum flow rates of 124 mL/min with hydrostatic pressures up to 2400 Pa [5].

For precise control, Chemyx’s Precision Fusion Series, SKE 70 OEM, and Fusion 6000X OEM pumps offer an accuracy of ± 0.35% and reproducibility of ± 0.05% for a full stroke [6].

Pressure Capabilities

High-pressure microfluidic applications often require specialized pump solutions. The Fusion 6000X high-pressure syringe pump is designed to dose viscous solutions and semi-solid materials against back pressure. Remember, back pressure refers to the resistance a fluid encounters as it flows through a system, like narrow channels or filters. This makes it suitable for microfluidic applications requiring flow maintenance against resistance.

Dead Volume Considerations

Minimizing dead volume is important for microfluidic applications where sample conservation is a consideration. Dead volume is the fluid that remains trapped within the pump or tubing and isn’t dispensed, which can be an issue for costly or rare samples. Thermally controlled back pressure regulators can achieve dead volumes as low as 3 nL with time constants of only a few seconds [7]. Chemyx syringe pumps are designed with minimal dead volume, supporting efficient sample utilization in experiments. Further details are available on our microfluidics applications page.

Application-Specific Requirements

Different research areas have different needs, right? What works perfectly for one application might not be ideal for another.

Drug Formulation Applications

Drug formulation research requires control over mixing ratios and flow rates. The Fusion 4000X syringe pump offers dual channel microfluidic flow control for consistent drug formulation results and the development of new therapies. Imagine creating tiny, perfectly mixed drug cocktails for testing — that’s where this level of precision truly shines.

Cell Biology Research

Cell culture applications benefit from non-pulsatile flow to maintain cell viability. While innovative designs like µTesla pumps integrated into 3D-printed microfluidic systems provide continuous, non-pulsatile flow [8], Chemyx pumps also deliver smooth, programmable flow, supporting stable conditions for cell viability in cell biology research applications.

Analytical Chemistry

Analytical applications require reproducibility and minimal carryover between samples. Syringe pump systems from Chemyx provide precision for analytical tasks due to their positive displacement mechanism and programmable control capabilities, which support repeatable data.

Selection Criteria for Microfluidic Pump Solutions

Choosing the right microfluidic pump solution can feel like a significant decision, but by breaking it down, it’s really about matching the pump’s capabilities to your specific experimental needs.

Flow Rate Range

Determine the required flow rate range for your application, considering both minimum and maximum needs, along with the ability to achieve intermediate flow rates with control. Chemyx offers a range of pumps to cover flows from nanoliters to milliliters per minute.

Pressure Requirements

Assess the system’s back pressure, including pressure drops across microchannels, filters, and other flow restrictions. Select pumps with adequate pressure capabilities that maintain flow rate control. For instance, the Fusion 6000X is well-suited for high-pressure scenarios.

Fluid Compatibility

Material compatibility is important. Consider chemical resistance, biocompatibility, and the potential for contamination when selecting pump components. Guidance on material selection for specific fluid compatibility requirements is available.

Control Requirements

Evaluate the need for external control interfaces, programmability, and integration with automated systems. Advanced pump controllers enable complex flow profiles and integration with laboratory automation platforms. Chemyx pumps feature intuitive interfaces and connectivity options for seamless integration.

Compare Chemyx Syringe Pump specifications for microfluidic applications here.

Advanced Integration Considerations

The capability for synchronizing multiple pumps, implementing complex flow profiles, and integrating with detection systems is often a key consideration in advanced microfluidic research.

Chemyx pump systems offer programmable control capabilities. These enable researchers to implement complex experimental protocols while maintaining precision for reproducible results. Chemyx pump systems are designed for adaptability to various research requirements.

Key Microfluidic Pump Specifications at a Glance:

| Specification | Description |

|---|---|

| Flow Rate Accuracy | The precision with which a pump can deliver a set flow rate. |

| Reproducibility | The ability of the pump to deliver the same flow rate consistently over multiple runs. |

| Pressure Capability | The maximum back pressure the pump can overcome while maintaining flow. |

| Dead Volume | The volume of fluid remaining in the pump or tubing that is not dispensed. |

| Programmability | The extent of control over flow profiles (e.g., ramping, pulsing, multi-step flows). |

| Fluid Compatibility | The resistance of pump materials to various chemicals and biological samples. |

Microfluidic Pump Selection Checklist:

- Does the pump offer the required flow rate accuracy and reproducibility?

- Can it handle the maximum back pressure of your microfluidic setup?

- Is the pump material compatible with all fluids being used?

- Does it offer programmable control for complex experimental protocols?

- Is the dead volume minimized for valuable or scarce samples?

- Is it designed for ease of integration into your existing lab automation?

- Does the manufacturer provide technical support and resources?

Limitations:

- Rapid technological advancements may introduce new pump solutions not covered in this overview.

- Specific application nuances might require further tailored consultation beyond general guidelines.

- Data presented for various pump types is derived from diverse experimental setups, which might limit direct comparisons.

- The focus is primarily on liquid handling, with less emphasis on gas or multi-phase microfluidics.

Next Steps: Future research should focus on developing standardized performance benchmarks for microfluidic pumps across various applications to facilitate easier comparison and selection.

For researchers requiring high-precision microfluidic pump solutions, our technical team can discuss specific application requirements and assist in identifying optimal pump configurations. Contact us today to enhance your microfluidic research.

Frequently Asked Questions (FAQ)

Q1: What are microfluidic pump solutions used for?

A1: Microfluidic pump solutions are utilized for fluid control in various advanced research fields, including drug discovery, cell biology, and analytical chemistry. They enable manipulation of minute fluid volumes.

Q2: How precise are Chemyx syringe pumps?

A2: Chemyx syringe pumps, such as the Fusion series, SKE 70 OEM, and Fusion 6000X OEM models offer an accuracy of ± 0.35% and reproducibility of ± 0.05% for a full stroke [6]. This supports consistent and verifiable experimental outcomes.

Q3: Can Chemyx pumps handle high-pressure microfluidic applications?

A3: Yes, the Chemyx Fusion 6000X high-pressure syringe pump is designed for high-pressure microfluidic applications. It doses viscous and semi-solid materials against back pressure.

Q4: How do Chemyx pumps address dead volume concerns?

A4: Chemyx syringe pumps are designed with minimal dead volume. This characteristic is important for applications requiring efficient sample utilization and conservation. More information can be found on our microfluidics applications page.

Q5: What features make Chemyx pumps suitable for cell biology research?

A5: Chemyx pumps deliver smooth, programmable flow. This capability supports stable, non-pulsatile conditions for maintaining cell viability in cell biology research applications.

Q6: What should I consider when selecting a microfluidic pump solution?

A6: Key selection criteria include the required flow rate range, system back pressure, fluid compatibility with pump materials, and control requirements for integration and programmability. These factors help ensure the chosen pump meets specific application needs.

Sources

[1] Combined Actuation of Microfluidic Pump Based on Piezoelectric Effect and Liquid Crystal Backflow Effect

[2] A Peristaltic Micro Pump Driven by a Rotating Motor with Magnetically Attracted Steel Balls

[3] A Low-Power CMOS Microfluidic Pump Based on Travelling-Wave Electroosmosis for Diluted Serum Pumping

[4] A One-Square-Millimeter Compact Hollow Structure for Microfluidic Pumping on an All-Glass Chip

[5] Miniature 3D-Printed Centrifugal Pump with Non-Contact Electromagnetic Actuation

[6] Chemyx Syringe Pumps

[7] Thermally controlled microfluidic back pressure regulator

[8] Monolithically 3D-Printed Microfluidics with Embedded Tesla Pump