What is microfluidics? Microfluidics is a multidisciplinary field dedicated to the science and technology of systems that manipulate minute quantities of fluids, typically in the microliter to picoliter range, using channels with dimensions of tens to hundreds of micrometers. For any microfluidic application to succeed, the ability to control fluid flow rate with exceptional precision and accuracy is not just beneficial—it is essential. Syringe pumps have emerged as a cornerstone technology for achieving this level of control.

Topics covered in this article:

- The Critical Role of Precision in Microfluidic Pump Systems

- Understanding Flow Control: Syringe Pumps vs. Other Methods

- Key Features of High-Quality Microfluidic Pumps

- Syringe Pumps for Microfluidics: Lab and Research Models

- Applications in Action: Chemyx Pumps in Microfluidic Research

- How to Choose the Right Microfluidic Syringe Pump

- Advance Your Research with Precision Syringe Pumping

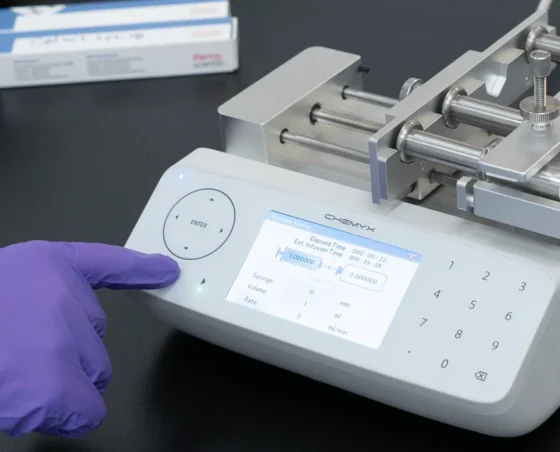

For researchers and engineers seeking the most dependable and accurate microfluidic pump solutions, Chemyx Inc. provides an industry-leading portfolio of syringe pumps. Chemyx Microfluidic Syringe Pumps are engineered for the exacting demands of research, offering the precision, accuracy, and reliability necessary to drive innovation.

The Critical Role of Precision in Microfluidic Pump Systems

A syringe pump for microfluidics grants researchers unparalleled command over fluid movement, which is vital for experiments characterized by extremely low flow rates and small volumes. This precise control is the key to unlocking a wide array of advanced applications, including:

-

Precise Reagent Mixing: Ensuring homogenous mixing of reagents within microchannels for consistent chemical reactions.

-

Gradient Generation: Creating stable chemical or biological gradients to study cellular responses like chemotaxis.

-

Targeted Delivery: Administering precise doses of drugs, reagents, or nutrients to cells or tissues in organ-on-a-chip models.

This level of control has fundamentally advanced biological procedures such as enzymatic assays, DNA analysis, and proteomics [1]. Furthermore, the ability of a high-quality microfluidic pump system to deliver accurate fluid volumes consistently over extended periods is critical for ensuring the reproducibility and validity of scientific research.

Understanding Flow Control: Syringe Pumps vs. Other Methods

When designing a microfluidic setup, the choice of flow control method is a critical decision. While pressure-driven systems are common, the flow characteristics of a syringe-pump-driven system offer distinct advantages for many research applications. A microfluidic syringe pump excels at providing a stable, pulseless flow and enables the programming of complex, time-varying flow profiles [2].

Other methods, such as passive capillary-driven flow, have their place in simpler devices. However, for complex experiments requiring dynamic control and high reproducibility, active methods using programmable syringe pumps are superior. The choice of pump can also significantly impact the experimental environment by influencing the shear stress exerted on cells or particles within the microfluidic device, making a stable flow profile essential for delicate biological studies [3].

Key Features of High-Quality Microfluidic Pumps

To achieve reliable and repeatable results, a microfluidic pump must possess several key characteristics. Investing in a pump with these features ensures your experimental setup is robust, flexible, and capable of producing high-quality data.

Smooth, Pulseless Flow

A steady, non-pulsating flow is a non-negotiable requirement in most microfluidic applications. Flow pulsations can disrupt delicate cell cultures, interfere with sensitive particle analysis, or cause inconsistent droplet formation in droplet-based microfluidics. To address this, premier microfluidic pumps, like the Chemyx Fusion series, are engineered with advanced stepper motors and driving mechanisms to provide exceptionally smooth, pulseless, and reproducible flow rates.

Wide Flow Rate Range and Programmability

Microfluidic research often demands operation at extremely low flow rates, sometimes in the microliter or even nanoliter-per-minute range. A high-quality pump must deliver these flows accurately. Equally important is programmability, which allows for the automation of multi-step experiments. This can involve ramping flow rates up or down, creating complex gradients, or synchronizing fluid delivery with other lab instruments like microscopes and sensors. Chemyx pumps empower users to design and execute these intricate experimental protocols, as shown in the extensive application of Chemyx syringe pumps.

Syringe and System Compatibility

A versatile microfluidic pump system should accommodate a wide variety of syringe types and sizes, including glass, plastic, and stainless steel, without sacrificing performance. Chemyx syringe pumps are designed to be “syringe agnostic,” featuring an adjustable holder that is compatible with virtually any commercially available syringe. To complete the system, using high-quality microfluidic fittings and appropriate tubing is crucial to prevent leaks, minimize dead volume, and ensure the integrity of your entire fluidic path.

Syringe Pumps for Microfluidics: Lab and Research Models

With a proven track record validated by over 20,000 citations in scientific publications, the Chemyx range of syringe pumps stands as a trusted solution for microfluidic applications worldwide. Our pumps are designed by scientists, for scientists, ensuring they meet the real-world demands of the modern laboratory.

Fusion 200X: A Versatile Lab Standard

The Chemyx Fusion 200X is an exceptional two-channel syringe pump offering programmable infuse and withdraw capabilities, making it a flexible workhorse for any lab. Its features make it an ideal choice for a vast range of microfluidic applications:

-

Syringe Capacity: Holds syringes from 0.5 µL to 60 mL.

-

Flow Rate Range: 0.0001 µL/min to 84.7 mL/min.

-

Expandability: Modular racks are available to expand its capacity for higher throughput experiments.

Whether you are performing organ/tissue perfusion or general bioscience research, the Fusion 200X delivers the precision and versatility you need to succeed.

Fusion 4000X OEM: For Custom Integrated Systems

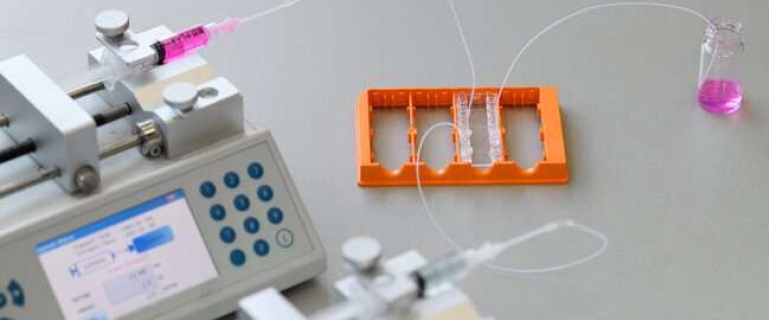

For researchers and engineers building custom analytical instruments, the Chemyx Fusion 4000X OEM is the ultimate bolt-on microfluidic pump module. This unit features two independently controlled motors, making it perfect for advanced applications that require dual-rate, push-pull, or complex oscillatory flow patterns. It is the engine behind cutting-edge research in areas like lipid nanoparticle (LNP) synthesis and automated microfluidic mixing for drug formulation.

Applications in Action: Chemyx Pumps in Microfluidic Research

The true measure of a pump’s performance is its success in real-world applications. Chemyx pumps have been instrumental in numerous breakthrough studies. For instance, the Fusion 4000 has been used to precisely mix ethanol and aqueous phases in a microfluidic chip for creating Lipid Nanoparticles (LNPs), a key technology in mRNA vaccine development. In other research, the same model was used to generate highly uniform, mono-dispersed micron-sized droplets by precisely controlling the injection of continuous and discrete phase liquids. For more detailed examples of how our pumps are used, you can see how our customers are using our pumps by reading our application of Chemyx syringe pumps.

How to Choose the Right Microfluidic Syringe Pump

Selecting the optimal microfluidic pump system is critical for achieving your research goals. The right choice will not only enable your current experiments but also provide the flexibility for future projects.

Factors to Consider

Before making a decision, evaluate your experimental needs against these key criteria:

-

Flow Rate & Precision: What is the required flow rate range (nL/min to mL/min)? How much precision is necessary?

-

Number of Channels: Do you need a single channel, dual channels, or a multi-channel setup?

-

Pump Capabilities: Is simple infusion sufficient, or do you require infuse/withdraw, push-pull, or programmable multi-step modes?

-

Pressure: What back pressure will the pump need to overcome in your microfluidic chip?

-

Budget: Balance the need for advanced features with available funding. Chemyx offers a range of models to fit various budgets without compromising on quality.

Comparing Chemyx Syringe Pump Models

To simplify your selection process, a direct comparison of specifications is helpful. Chemyx offers a diverse lineup of high-precision syringe pumps to meet every need. Consider the following key parameters when comparing models:

| Feature | Chemyx Fusion 200X | Chemyx Fusion 4000X | Chemyx HP1 High-Pressure |

|---|---|---|---|

| Syringe Size Range | 0.5 µL–60 mL | 0.5 µL–100 mL | 1 mL–400 mL |

| Mode | Infuse/Withdraw | Dual Independent Infuse/Withdraw | Infuse/Withdraw |

| Linear Force | 45 lb | 85 lb | 2,200 lb |

| Max Flow Rate | 85 mL/min | 170.5 mL/min | 200 mL/min |

| Ideal Application | General Microfluidics, Perfusions | Complex Mixing, Lipid Nanoparticle (LNP) Synthesis | High-Pressure Encapsulation, Hydraulic Fracturing |

Conclusion: Advance Your Research with Precision Syringe Pumping

In the rapidly evolving fields of biology, chemistry, and medicine, high-precision microfluidic pumps are indispensable tools that enable groundbreaking discoveries. As they provide the control and reliability needed to explore cellular mechanics, develop novel diagnostics, and formulate next-generation therapeutics.

Chemyx Inc. is committed to empowering this research by offering a comprehensive lineup of syringe pumps engineered for the accuracy, flexibility, and robust performance required in microfluidics. Explore the full range of Chemyx products to find the perfect pump to accelerate your discoveries. For expert guidance in selecting the right product for your specific application, contact the experienced engineering team today.