In the 3D printing wave, many forms arise to get new designs which allow easy fabrication. Typically, 3D printers use filaments to produce patterns in surfaces by applying the polymers in a hot surface with an XYZ Cartesian control. Meanwhile, the thread is melted and extruded to provide enough layers. However, biological applications require materials which are different from the thermoplastic filaments like PLA (polylactic acid) or ABS (Acrylonitrile butadiene styrene). Take for example food printers, these devices are loaded with syringes which contain viscous fluids like pasta or biopolymers which are extruded and follow the patterns for new intricate designs.

There are different applications for the integration of 3D actuators and syringe pumps as:

- 3D Electrospinning Tissue Scaffold.

- 3D Electrospinning for energetics as electrode materials.

The materials for this enterprise have also been discussed by authors working with Do-It-Yourself devices. However, the idea is to use the high control of commercial syringe pumps to direct the flow with high precision.

3D Electrospinning Tissue Scaffold

It is possible to create new 3D scaffolds using syringe pumps to aligned cells and mimic the cell orientation of living tissues. Different authors have proved that electrospinning can produce 3D nanofibers, in this way costume designs are obtained for the production of new micro-architectures in the form of tissues. For instance, Chemyx syringe pumps can be implemented to control fiber orientation. The engineers coupled the Cartesian systems and the syringe pumps to obtain 3D bio-material scaffolds. After achieving the fiber alignment; techniques as green fluorescent protein indicators show the viability of the cells in the engineered tissue (Derek et al., 2016)

3D Electrospun of electrode materials

The production 3D (3-dimensional) porous silver nonwoven mats were demonstrated using a spray nozzle which is located about 6 cm above the sample stage to minimize the effects of air circulation in the fume hood. Scientist designed the homemade spray-coating equipment with a motorized 2-axis moving scene using heating element for coating the homogeneous electrode. The solution was pumped through a nozzle with a Chemyx syringe pump at 250 ml/min. For instance, an aerosol is formed using nitrogen (1 bar) as a carrier inert gas, and a regulator maintained a stable pressure (Jang et al., 2015).

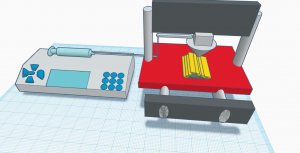

Figure 1. A Chemyx syringe pump conjugated with a Cartesian system as a 3D printing device for the elaboration of porous silver nonwoven mats as an example. The system can is adapt for other printing procedure as cells or biopolymers.

Recent studies

Bioprinting has take a step further and 3D printing applications as developed by Feinberg group are taking the lead; opening the exciting possibilities that these devices provide to the healthcare field. They made a syringe integrated system to avoid the time delay they use a NEMA 17 which we already discussed in Chemyx website. The system itself enable the printing of complex shapes or objects (Pusch et al., 2018). Also, they used with the process of printing 3D hydrogels which are useful in health care studies.

Meyer’s group has also developed a technology that combines bacterial films to form new materials with the reproducible. A commercial 3D printer was modified for these new bacterial systems with alginate-based bio-ink chemistry. Syringe pumps may also be integrated to produce this type of extrusion(Lehner et al., 2017).

Summary

The integration of syringe pumps as 3D printers provide the opportunity to work different materials, as chitosan, agar, alginate, and cells for tissue patterning. Is essential to coordinate the Cartesian system with the syringe pump but the window to integrate both systems is opened, and it will allow the development of complex biological structures which were not constructed before.

Different syringe pumps can be allocated for 3D printing devices, the applications are vast, and the Chemyx syringe pumps provide the accuracy for the best performance delivering viscous materials. Syringe pumps with Cartesian devices easily achieve techniques as electrospinning; therefore, custom applications are developed for tissue engineering and catalytic material optimization. If you want to know more about Do-it-Yourself syringe pumps and the differences with high-performance syringe pumps offer by Chemyx, please visit the Chemyx website to learn more.

Bibliography

- Derek, B., Grace, D., Dow, T., Sellman, Z., 2016. 3D Electrospun Tissue Scaffold: Achieving Customized Fiber Alignment. Worcester Polytechnique Institute.

- Jang, Y., Jo, J., Choi, Y.M., Kwon, S., Kim, K.Y., 2015. 3D (3-dimensional) porous silver nonwoven mats prepared with cellulosic templates and spray equipment for use as supercapacitor current collectors. Energy 93, 1303–1307. https://doi.org/10.1016/j.energy.2015.10.013

- Lehner, B.A.E., Schmieden, D.T., Meyer, A.S., 2017. A Straightforward Approach for 3D Bacterial Printing. ACS Synth. Biol. 6, 1124–1130. https://doi.org/10.1021/acssynbio.6b00395