Mud Injection

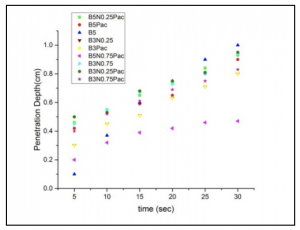

Mud injection test was carried out by entering the prepared mud slurry into the syringe of a Nexus 6000 syringe pump system (Chemyx, USA).The fluid penetration test at 1 ml/h injection rates lasted for 30 minutes. As seen in figure 3, B5N0.75PAC had minimum filtrate penetration into the micromodel. Obviously, lower filtrate penetration depths will be associated with less formation damage. The base mud (B5) caused maximum formation damage during the very first minutes and the filtrate penetrated deeply into the porous media. Bulletin de la Société Royale des Sciences de Liège, Vol. 86, special edition, 2017, p. 201 – 205

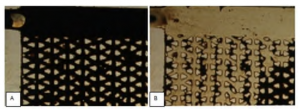

Figure 4 shows the wellbore of the main channel when the cake had not yet formed. Consequently, almost all oil is driven out of the formation. This figure indicates the necessity of creating the filter cake to decrease fluid loss. The following figure depicts the injection of B3N0.25 into the micromodel. As mentioned earlier, low concentration nanoclays are highly lubricating and they can reduce the level of viscosity.

Conclusions

Comparison between mud samples with and without nanoclay revealed that at high shear rates, adding nanoclay improved the reduction in viscosity by up to two times. According to dynamic tests, the penetration depth of the formulation containing nanoclay and PAC (B5N0.75PAC )was about 1.5 times less than that of the base mud.

Acknowledgment

The authors would like to thank the IKIU nano-tech unit and micromodel laboratory of institute of petroleum Engineering of Tehran University for their financial and technical supports

Read Full Article Here: Evaluation of PAC with Nanoclay as drilling mud