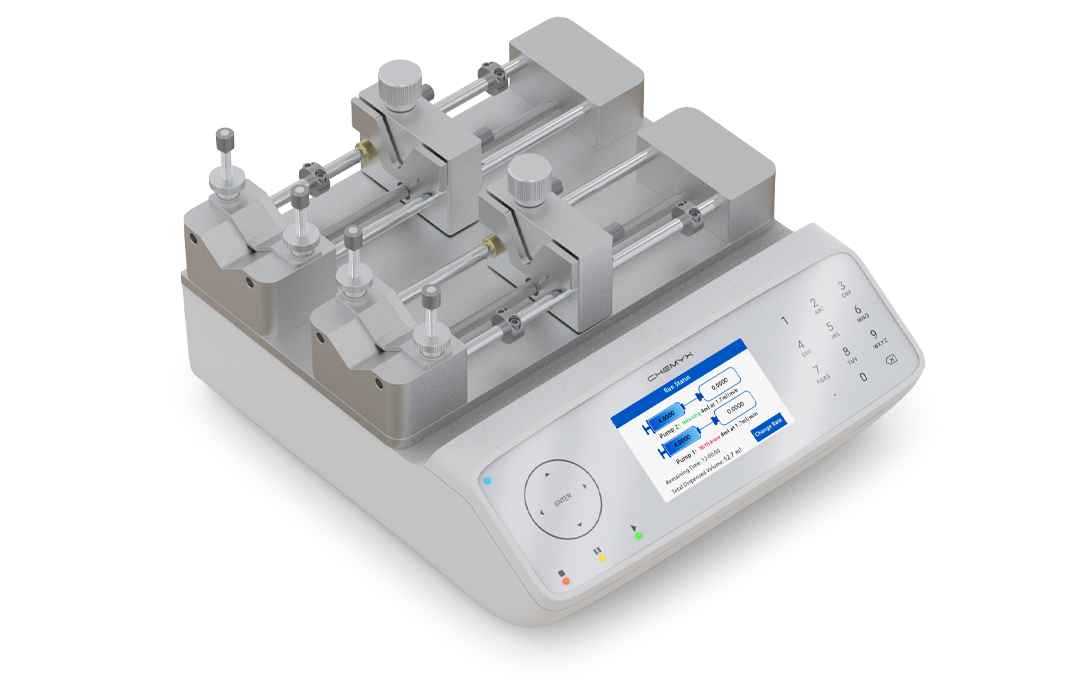

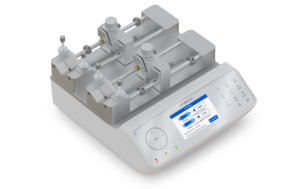

Fusion 4000X Dual Independent Channels Syringe Pump

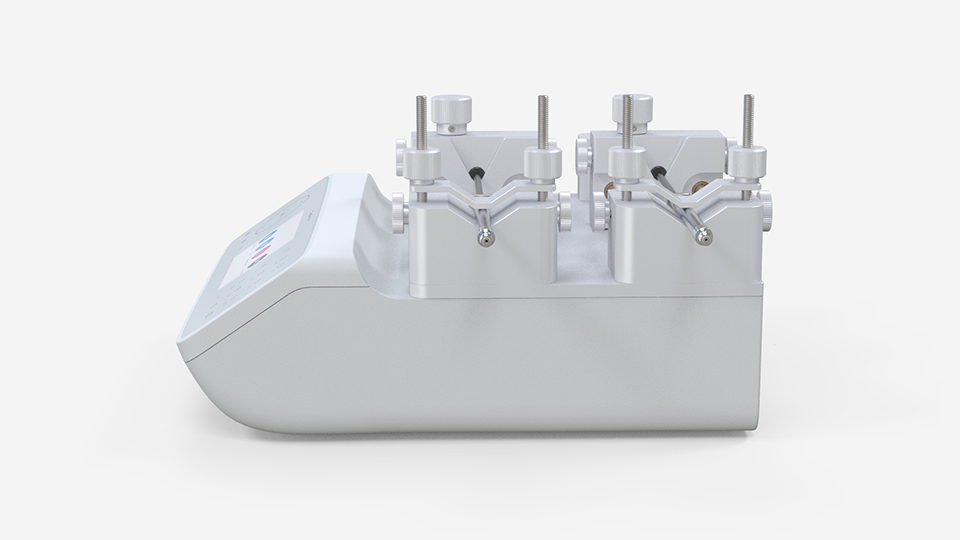

The Fusion 4000X is a high precision multi-syringe syringe infusion pump with dual-independent infuse and withdraw channels and programmable step-rate function. The Fusion 4000X multi-channel syringe pump has an add-on 2-syringe push and pulls rack to increase the syringe number to four. This system allows for complex dual-rate, push-pull, and oscillatory flow requirements for difficult research applications. With an all-glass interface and machined metal design, the Fusion syringe pumps are chemical resistant and have high superior durability for lab environments of all types... View Product Details

The Fusion 4000X motorized multi-channel syringe infusion pump features:

- 2 separate pump drives capable of independent pulseless, reproducible rates, and movement

- Programmable multi-step and cycle mode that allows users to input complex flow profiles or perform flow cycling from a computer LabVIEW or the pump itself

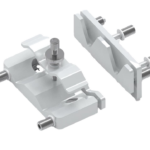

- Can be expanded with a 2-syringe push and pull rack attachment to increase the total syringe capacity to four

This motorized multi-channel syringe infusion pump system is designed for a wide range of biopharmaceutical research like lipid nanoparticles, microfluidic mixing, and lab-on-chip flow control in drug formulation applications and more; with precision machined metal design, the Fusion 4000-X dual-channel syringe pump is easy to clean, for lab and GMP environments.

- 2 Independent pump channels

- Holds syringes from 0.5µL to 100mL

- Rates from .0001 µL/min to 170.5 mL/min

- Touchscreen, USB, RS232, TTL control

- Free Programmable Mode Included

- Serial Pump connections through RS485

- Dual Syringe Holding Rack available

- 2-Year Limited* Warranty

- Available Accessories