The following sections are covered in this article:

- Key Performance Metrics for Syringe Pump Evaluation

- Factors Influencing System-Level Accuracy

- Comparison of Leading Syringe Pump Models

Precision syringe pumps and high pressure syringe pumps are essential instruments in modern research and industrial laboratories. With their ability to deliver precise, pulseless, and reproducible fluid volumes is for applications ranging from microfluidics and analytical chemistry to pharmaceutical development and novel material discovery [1]. Unlike medical infusion pumps, laboratory syringe pumps are engineered for science applications where accuracy and high reproducibility are paramount [2]. Selecting the optimal pump requires a systematic evaluation of performance metrics and an understanding of how system components collectively influence accuracy.

Key Performance Metrics for Syringe Pump Evaluation

The performance of a syringe pump is defined by several key parameters. These metrics determine the instrument’s suitability and stability for specific laboratory tasks, from high-pressure chemical synthesis to delicate cell culture perfusion.

Flow Rate Range and Precision

A primary function of a syringe pump is to control the flow rate of a liquid. The required range can vary dramatically depending on the application.

- Microfluidics and Nanotechnology: These fields often demand extremely low, stable flow rates. Some pumps can achieve flow rates as low as the picoliter per minute range [3].

- General Laboratory Use: A broad operating range provides versatility. Some models deliver flow rates from the picoliter per minute range up to tens of milliliters per minute [4].

- High-Throughput Applications: For larger volumes or faster processes, higher flow rates are necessary. Certain pumps can deliver up to hundreds of milliliters per minute [5].

A pulseless flow is essential for sensitive analytical techniques like mass spectrometry and chromatography, where fluctuations can introduce noise and compromise results [1].

Accuracy and Reproducibility

Accuracy refers to how close a dispensed volume is to the target value, while reproducibility, or precision, is the consistency of results across multiple operations.

- Accuracy: High-precision models typically specify an accuracy of ±0.35% [6].

- Reproducibility: This is often a more critical parameter for ensuring consistent experimental conditions. Some OEM modules designed for integration into analytical instruments can achieve reproducibility of ± < 0.05% [7].

It is important to recognize that mechanical limitations and the working principle of the syringe can introduce errors that are only partially mitigated by equipment design [8].

Force and Pressure Capability

Dispensing viscous fluids, semi-solid materials, or working against significant back-pressure requires a pump with substantial linear force.

- Some high-force syringe pumps are engineered with linear pushing forces suitable for high-pressure applications.

- Such pumps must be paired with appropriate syringes. Stainless-steel syringes are designed for high-pressure environments, with some models rated for pressures up to 350 bar (approximately 5076 psi).

Factors Influencing System-Level Accuracy

The syringe pump is only one part of the fluid delivery system. Overall accuracy is determined by the interplay between the pump, the syringe, and the physical setup. The least accurate component in the system dictates the final measurement accuracy [9].

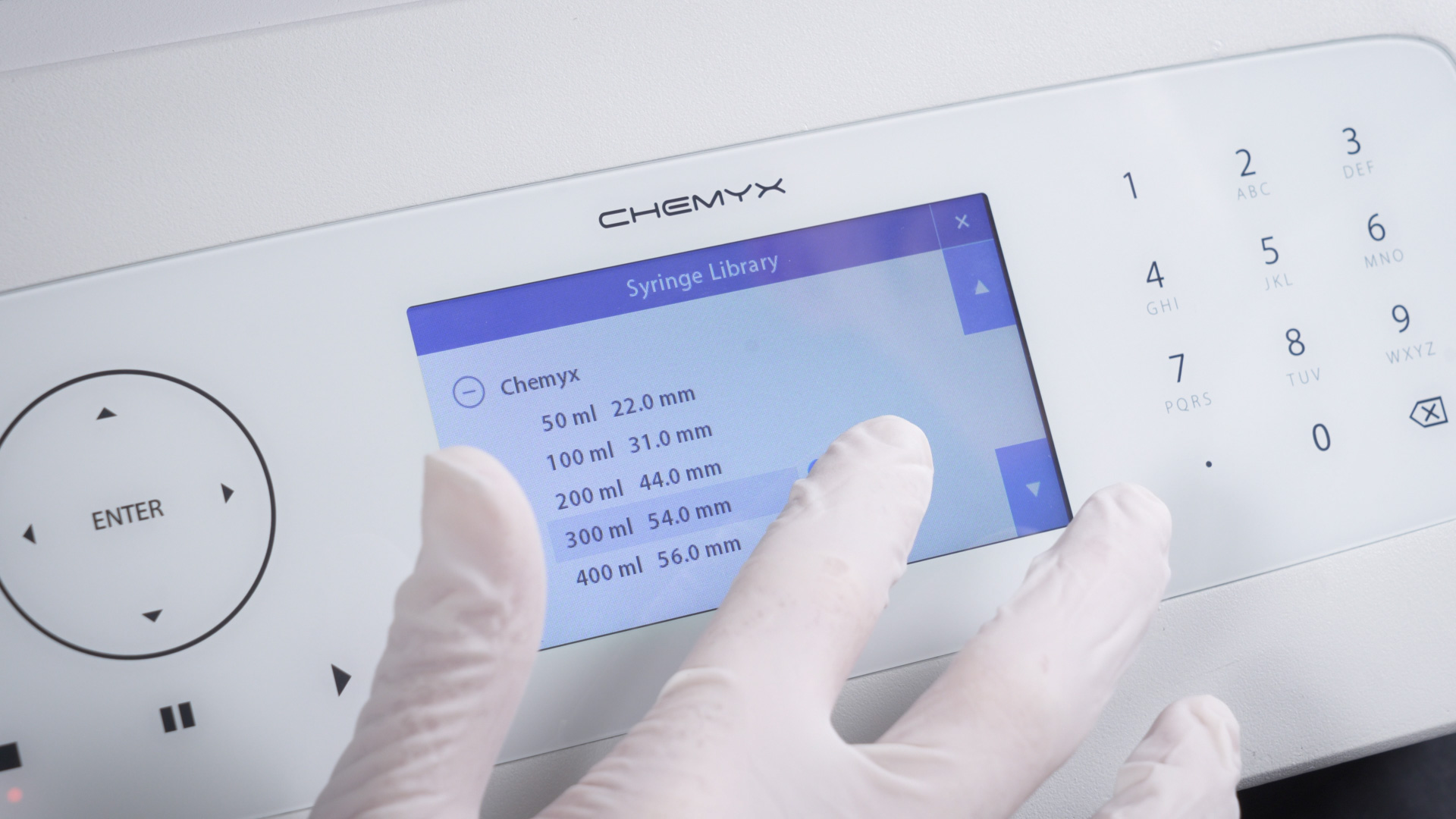

Syringe Selection

The choice of syringe has a direct impact on precision.

- Volume and Size: For optimal accuracy, the dispensed volume should be at least 20–50% of the syringe’s nominal capacity. Using a larger syringe to dispense a larger volume generally improves measurement precision [9].

- Material: The syringe material must be chemically compatible with the fluid being dispensed. Glass, plastic, and stainless steel are common options, with stainless steel being the standard for high-pressure applications [5].

Physical Setup and Calibration

The configuration of the experimental setup can introduce variability, particularly at low flow rates. The height and position of the pump relative to the infusion line can significantly affect flow accuracy [8]. Formal calibration methods, such as gravimetric and interferometric techniques, can verify and quantify flow rate accuracy, achieving uncertainty values as low as 5% for flow rates down to 0.01 mL/hr [8].

Control and Programmability

Today’s modern syringe pumps enhance laboratory efficiency by automating fluid handling [1].

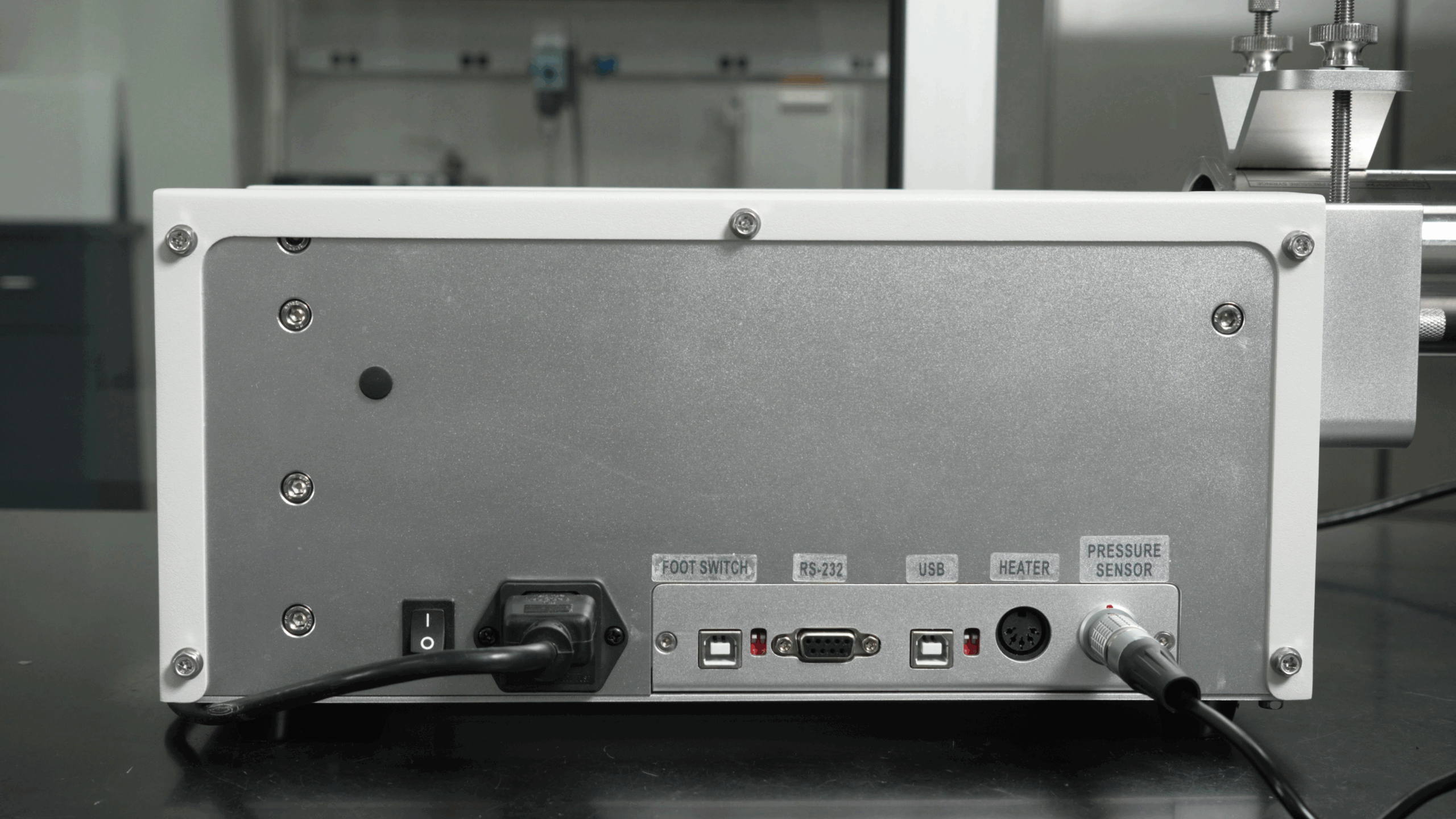

- Connectivity: Control via USB, RS232, and TTL ports allows for integration with computers and other laboratory instruments, enabling automated and reproducible workflows [5].

- Programmability: Advanced models offer programmable multi-step modes to execute complex sequences, such as oscillatory, ramping, or dual-rate flows [5].

Comparison of Leading Syringe Pump Models

Selecting the best precision syringe pump depends on the specific requirements of the application. The following table compares several leading models based on key performance characteristics.

| Model | Key Feature | Flow Rate Range | Accuracy | Max Force / Pressure |

| Fusion 200X | Dual-channel Infuse/Withdraw | 0.0001 µL/min to 85 mL/min | ± < 0.35% | 45lbs (20.4kg) |

| Fusion 4000X | Independent Multi Channel Infuse/withdraw | 0001 µL/min to 170.5 mL/min | ± < 0.35% | 85lbs (38.5kg) |

| Fusion 6000X | High Pressure, High Precision | 0.0001 mL/min to 408 mL/min | ±0.35% | 700lbs (318kg) |

| HP1 | Heavy Duty High Pressure | 0.01 ml/min to 2061 ml/min | ±0.35% | 2200lbs (907kg or 1 ton) |

| HP6 | Ultra High Pressure | 0.04 mL/min to 734 mL/min | ±0.2% | 22046lbs (10000kg or 10 tons) |

Conclusion

The selection of a precision syringe pump or high pressure syringe pump is a critical decision that directly impacts the accuracy and reproducibility of laboratory results. A thorough evaluation must extend beyond the pump itself to consider the entire fluidic system, including syringe size, material compatibility, and physical setup. By carefully matching pump capabilities with application demands, researchers can ensure the highest level of precision and reliability in their work, accelerating discovery and innovation across scientific disciplines.

Citations

[1] https://chemyx.com/resources/knowledge-base/general-syringe-pump-info/what-is-a-syringe-pump-3/

[2] https://www.air-tite-shop.com/Articles/syringe-pumps-and-syringes-for-laboratory-use

[3] https://chemyx.com/resources/knowledge-base/general-syringe-pump-info/micromanufacturing-and-microdispensing-applications-with-syringe-pumps/

[4] https://chemyx.com/resources/knowledge-base/general-syringe-pump-info/syringe-pump-vs-infusion-pump/

[5] https://www.labx.com/resources/which-syringe-pump-and-type-of-syringe-is-right-for-my-lab/5353

[6] https://chemyx.com/syringe-pumps/fusion-200x/

[7] https://chemyx.com/syringe-pumps/oem-module/

[8] https://pmc.ncbi.nlm.nih.gov/articles/PMC10023007/

[9] https://www.ossila.com/pages/syringe-pump-accuracy-precision